Description

Product Parameters:

- Power: 110V/220V AC, 60Hz/50Hz

- Dimensions: L4530 × W2840 × H1690 mm

- Speed: Approximately 300-500 pcs/hour (depending on actual process conditions)

- Weight: Approximately 1600 kg

- Air Pressure: 4–6 kg/cm²

Product Description:

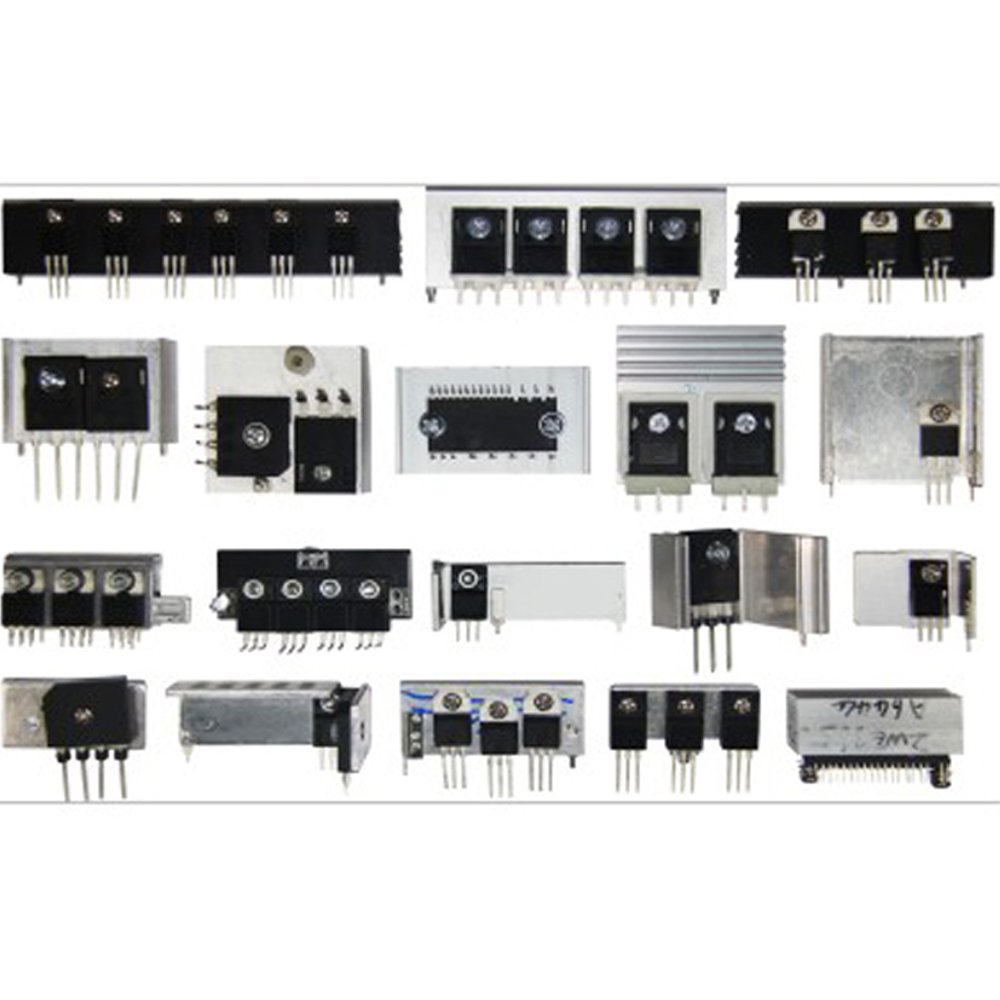

- This machine is a fully automated system that completes multiple processes on heatsinks, including automatic transistor lead trimming, thermal paste application, insulation sheet and pellet placement, transistor mounting, and screw fastening.

- The automated workflow includes: heatsink feeding → thermal paste application → insulation sheet loading → secondary paste application → transistor lead trimming and feeding → automatic insulation pellet placement → automatic screw fastening → product discharge, repeated continuously.

- The equipment features a modular inline structure capable of supporting complex assembly processes across numerous workstations. Depending on requirements, it can be configured with multi-level conveyor lines or rotary indexing tables.

- Each workstation is independently adjustable, reducing debugging complexity. Many stations are designed as complex assembly units, maximizing functional integration.

- This is a custom non-standard machine tailored to meet specific customer assembly processes and maximize production efficiency.

- Constructed with an aluminum profile frame, the machine is compact, space-saving, and highly efficient.

- It is controlled by Mitsubishi or Panasonic PLCs with a user-friendly touchscreen HMI for easy operation and learning.

- The machine uses imported SMC or Airtac cylinders, magnetic sensors, and solenoid valves, ensuring long service life.

- With excellent stability and high automation, this mature model is widely used in similar factories.

- It significantly reduces labor costs, replacing the work of approximately 10 operators with a single machine.