Product Parameters:

- Power Supply: 220V AC, 50Hz

- Dimensions: L1700 × W1500 × H1600 mm (subject to change based on workstation layout)

- Air Pressure: 4–6 kg/cm²

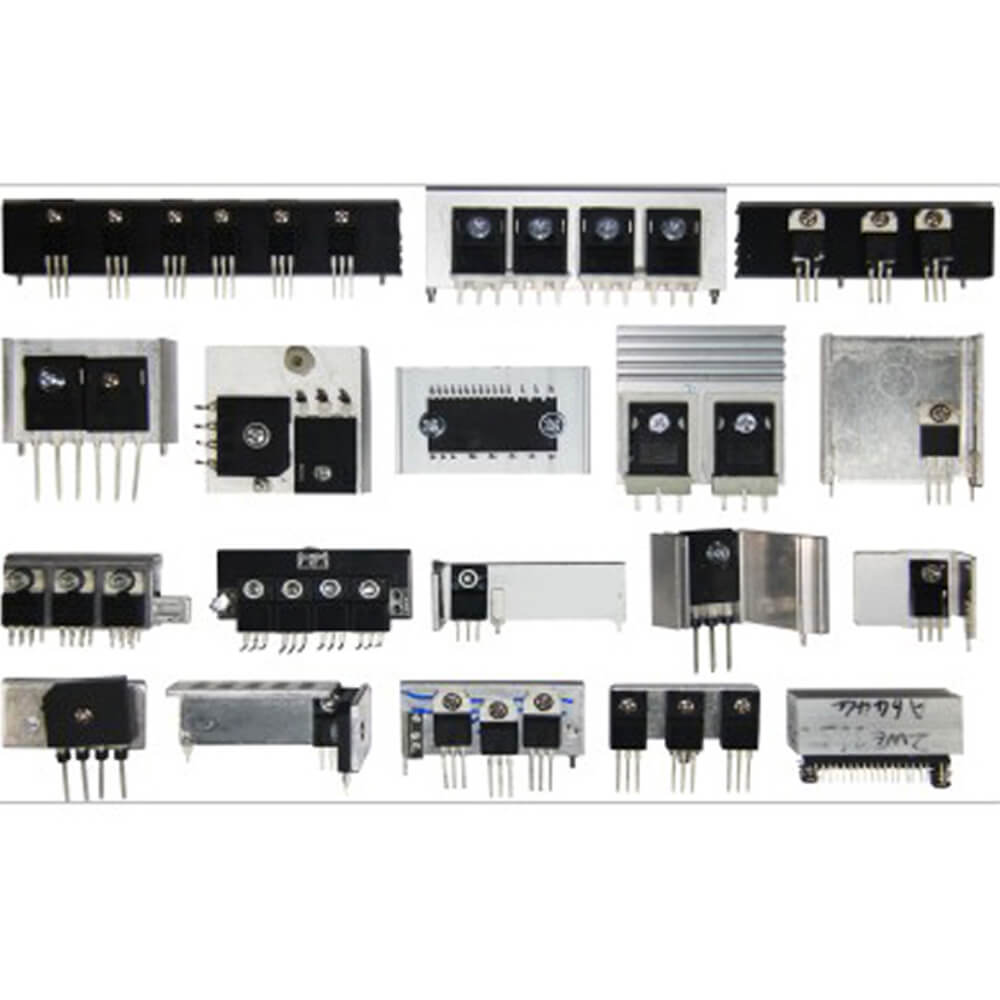

- Transistor Feeding Method: Tube-packed or bulk

- Heatsink Feeding Method: Bulk

- Production Capacity: 1000–1200 pcs/hour

- Power Consumption: 1500W

- Machine Weight: Over 650 kg

Product Description:

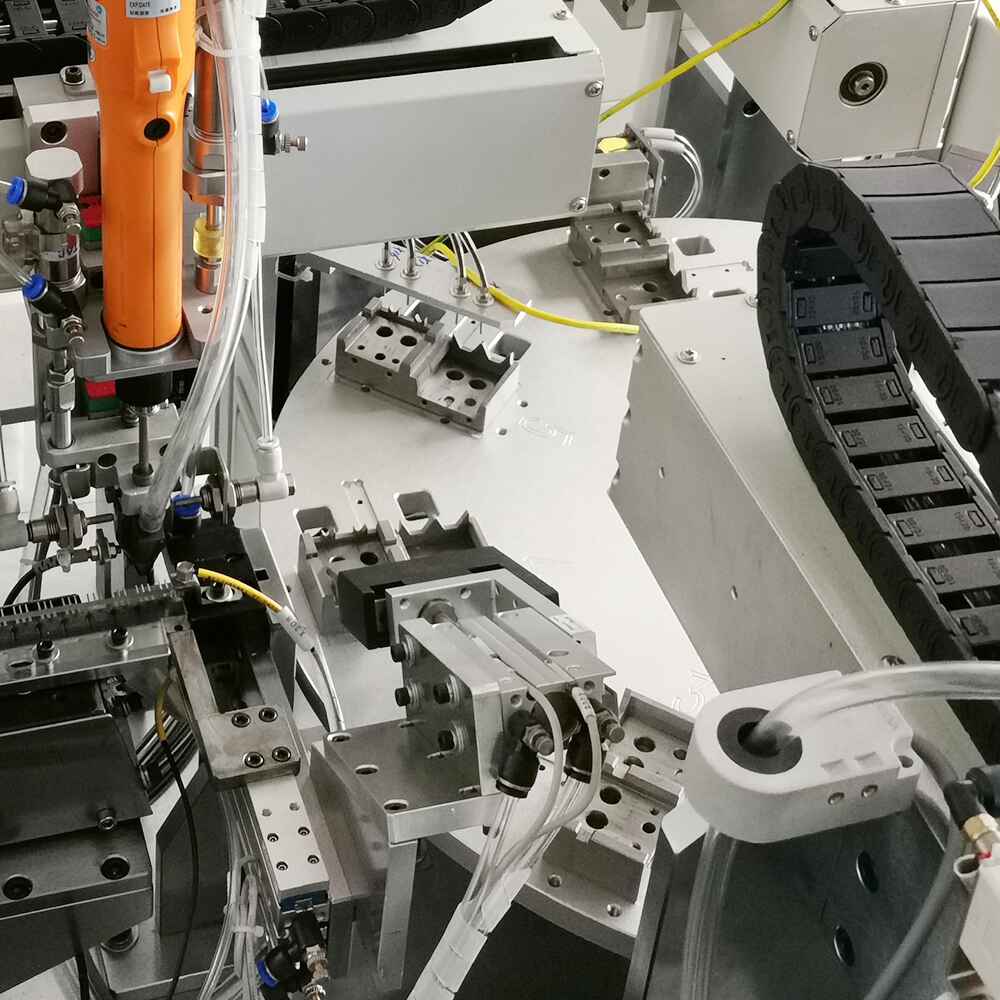

- This equipment is a fully automatic screw fastening machine specifically designed for mounting transistors (MOSFETs) onto heatsinks.

- It operates using a rotary indexing table with a high-precision divider, completing each task at dedicated workstations. Depending on the combination of transistors and heatsinks, the machine supports two working modes:

1.Heatsink with Nut Configuration:

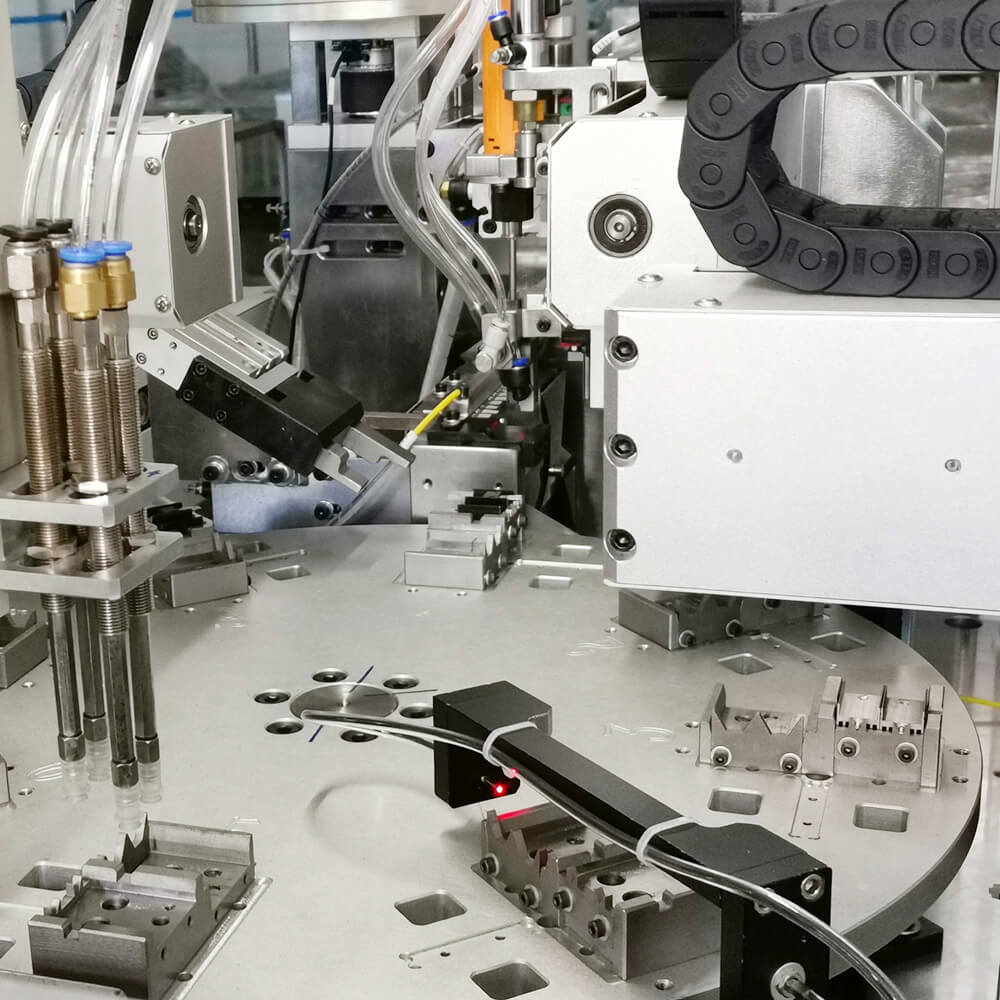

Nuts are automatically fed via a vibration bowl and placed onto fixtures on the rotary table by a robotic arm. Transistors, either tube-packed or bulk, are automatically lead-trimmed, formed, and fed onto the nuts in the fixture. In the next station, thermal grease is applied. Then, the heatsink is placed on top of the transistor. After that, screws are automatically fed and fastened. Finished products are removed by a robotic arm. This cycle repeats continuously.

2.Heatsink without Nut Configuration:

The heatsink is placed in the fixture. Tube-packed transistors (MOSFETs) are automatically arranged, trimmed, and formed. After thermal grease is applied, a robotic arm places the transistors onto the heatsink, followed by automatic screw fastening. Each heatsink can have multiple transistors fastened at different workstations. Completed assemblies are automatically removed by a robotic arm. The process runs in a continuous loop. - All screw fastening processes are fully automated. Different types of heatsinks can be accommodated by changing the fixture on the rotary table. The number of transistors (MOSFETs) per heatsink can be increased or decreased, and workstation functions can be customized based on fastening requirements.

The machine supports fastening multiple transistors onto a single heatsink.

Controlled by a Mitsubishi PLC and operated through a touchscreen HMI, the system is user-friendly and easy to operate. - Equipped with imported indexing mechanisms for precise positioning, the machine offers excellent stability and a low defect rate.

- With a high level of automation, the machine requires only one operator to manually load the heatsinks (if heatsinks are uniform, they can also be automatically fed via vibration bowls). More than 10 transistor tubes can be loaded at once for continuous automatic feeding. All other processes are fully automated. This machine significantly reduces manual labor and is widely used in power electronics manufacturing.