Product Parameters:

- Power Supply: 220V, 50Hz

- Dimensions: L1200 × W800 × H1580 mm (single unit size)

- Weight: Approximately 350 kg per unit

- Speed: Output capacity depends on product configuration and process settings.

Product Description:

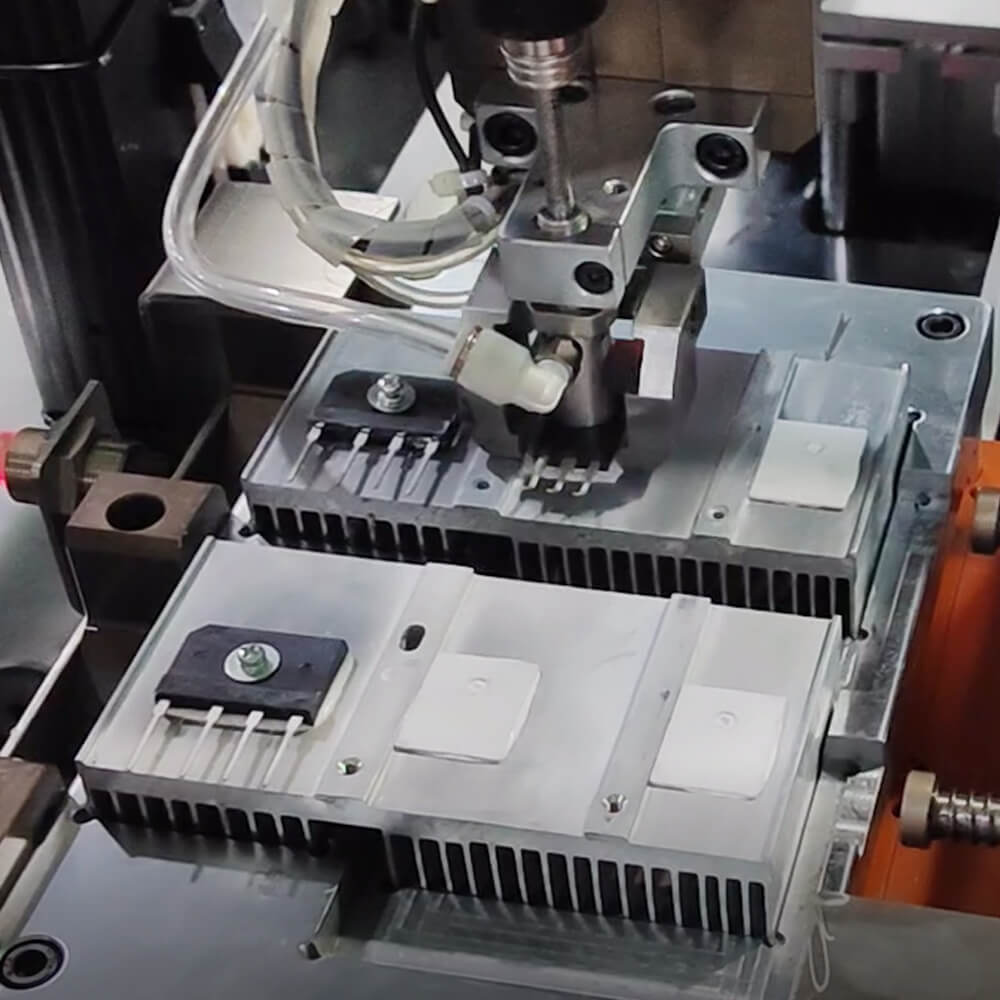

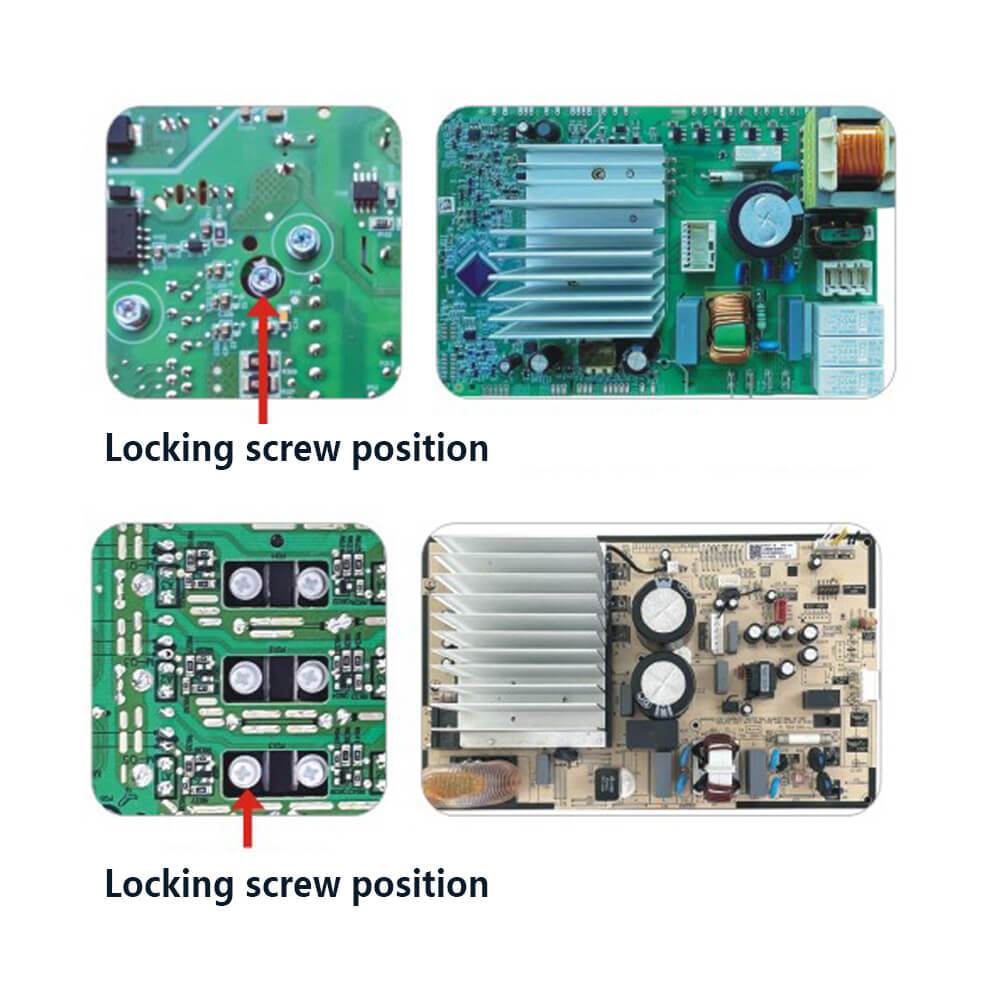

- FL-917A Heatsink and Semiconductor Assembly Machine for Power Electronics machine is an ideal fully automated screw fastening solution for products requiring multiple transistor mounting on a single heatsink or control board, with support for segmented torque control across multiple screws.

- Complex processes such as automatic transistor lead forming and feeding, thermal paste dispensing, visual inspection, clip fixing, pressure holding, and screw fastening can all be performed step-by-step on this equipment.

- The system is composed of multiple integrated yet independent units, each dedicated to a specific task. During transport, the product moves sequentially through each station with high positioning accuracy.

- The machine is controlled by a Mitsubishi PLC and touchscreen HMI. It supports a wide range of transistor packages including TO-220, TO-247, and bridge rectifiers.

- Flexible material feeding options: bulk transistors can be arranged via vibration bowl feeders, while tube-packed transistors can be loaded via magazine racks.

- This is a custom-built system. Similar products can be processed within its working range, and programs can be edited, stored, and recalled within the PLC.

- All operations are performed in dedicated workstations with independent mechanisms, making adjustment and changeover easy.

- Easy to operate and maintain, with an extremely low defect rate. Torque is adjustable, and multi-stage screw fastening can be performed on a single screw.