Product Parameters:

- Power: 220V AC 50HZ

- Size: Approximately L5000 x W2000 x H1900mm (varies based on equipment configuration)

- Speed: Approximately 300-500 sets/hour (depending on product process)

- Weight: Approximately 4000kgs (varies based on equipment configuration)

- Air pressure: 4-6 kg/cm²

Product Description:

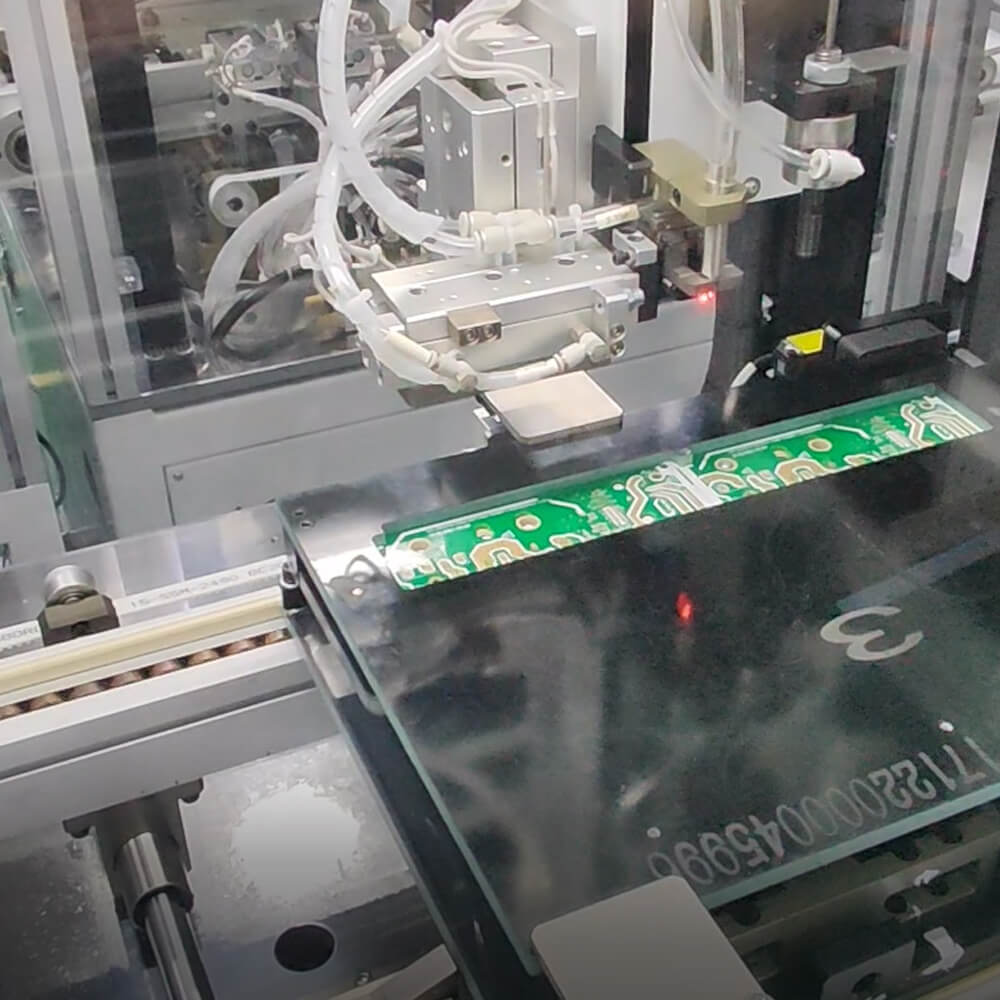

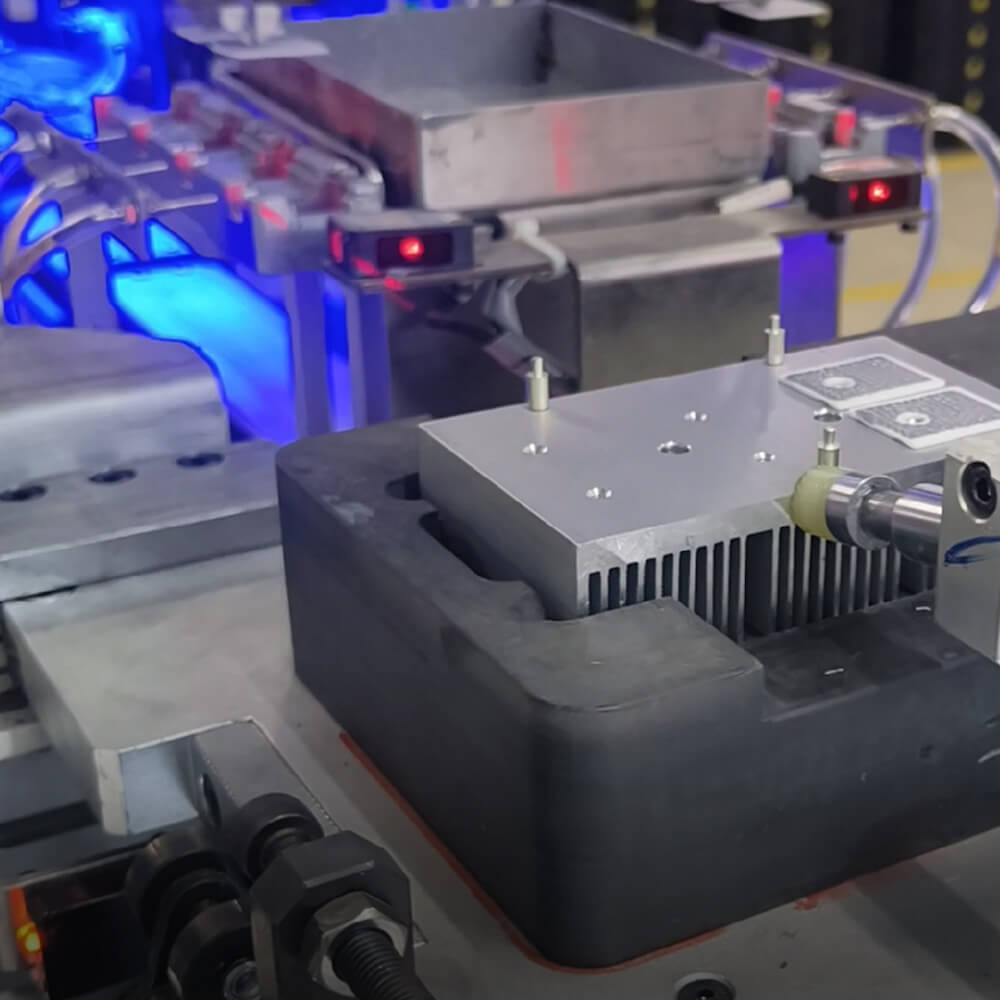

- FL-917B-Automatic Multi-Transistor Heatsink Assembly Line is designed for the assembly of multiple IGBTs/transistors and heat sinks, fully automating the entire process. The high automation level requires only manual placement and removal of the heat sink from the reflow fixture, with all other processes fully automated.

- The fully automated workflow is as follows: manual placement of the heat sink – single-sided thermal paste application – application of thermal paste on the other side of the ceramic sheet – detection and placement of ceramic sheet – feeding and placing the transistor – screw locking – inserting heat shrink tubing or rubber pads – manual removal of finished products – repeated cycle.

- The equipment adopts a fixture reflow system with a compact design and high flexibility. It allows for easy fixture replacement to accommodate different product specifications. Various workstations can be shielded, turned on/off, or replaced based on different assembly processes, ensuring high compatibility.

- The IGBT feeding process can be enhanced with additional functions such as automatic placement of magnetic beads, heat shrink tubing, and dust protection caps.

- The device performs precise scientific planning based on the time taken for each process, ensuring optimal equipment allocation at each workstation and optimizing the workflow to maximize processing efficiency.

- For high-precision steps, visual and precision sensing methods are used for accurate inspection, ensuring the quality and consistency of each process and the final product.

- To ensure high-quality screw locking for IGBTs and transistors, intelligent electric screwdrivers are used with torque segmentation, protecting sensitive components and preventing ceramic sheet breakage.

- The thermal paste application is carried out using pad printing or screen printing methods, ensuring even application and high consistency.