Product Parameters:

- Power Supply: 110V/220V AC 60Hz/50Hz

- Dimensions: L450 * W350 * H350 mm

- Weight: 15 kg

- Power: 25W

Product Description:

- Compact and Simple Structure, Easy to Operate

- The machine features a small, straightforward design, making it user-friendly and simple to operate, even for new users.

Wide Processing Range, Compatible with Various ICs - The machine supports a wide range of IC types, making it highly versatile for different applications and production needs.

Special Feeding and Stop Mechanism, Low Failure Rate - Equipped with a unique feeding and stopping mechanism, the machine has a low failure rate, ensuring consistent, reliable performance.

- Japanese Imported Steel for Die Molds, Long Service Life

- The die molds are made from high-quality Japanese steel, offering extended durability and longevity for continuous operation.

Impact Type, Stable Processing Dimensions - The impact-type processing system ensures that the processing dimensions remain stable for precise and consistent results.

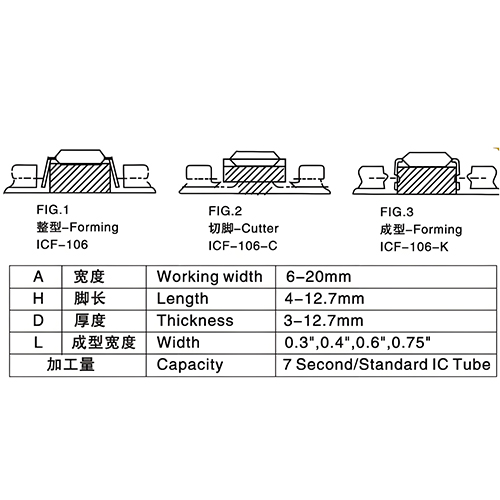

- FLG.1 is the standard model with two tracks: 0.3mm and 0.6mm.

- FLG.2 and FLG.3 are custom models that need to be purchased separately. These combine three functions into one machine.

- Custom models require dimension drawings for manufacturing.