Product Parameters:

- Power Supply: 220V 50Hz

- Dimensions: L1655W630H1080mm

- Weight: 450kg

- Speed: 1500PCS/H

Product Description:

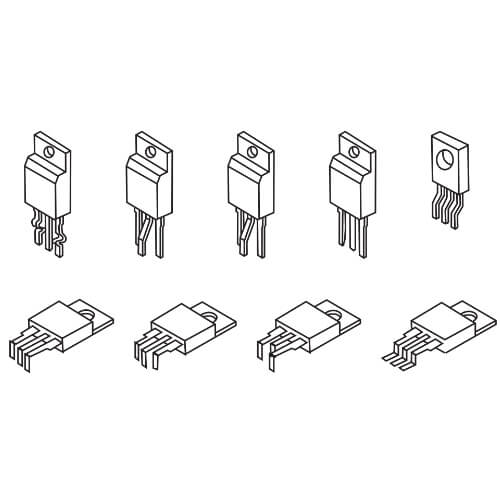

- Bulk transistors are automatically fed by a vibrating bowl, with parts distributed along a linear track, ensuring stable feeding.

- After distribution, the transistors are conveyed in a staggered manner through a slot and transported to the forming station. The formed components are then automatically ejected into the corresponding collection box.

- The machine’s key feature is its ability to install six sets of molds with different forming dimensions. Switching between these six mold shapes is simple and can be easily adjusted.

- Processed transistors are automatically ejected, with automatic counting functionality.

- The equipment is controlled by a Mitsubishi PLC and a human-machine interface touchscreen. Molds are made from imported steel, ensuring long-lasting durability.

- The entire operation is fully automated, requiring no human intervention except for loading and unloading parts.

- All actions are performed in designated workstations, with each workstation structure completely independent, making it easy to adjust and replace.

- The equipment is easy to operate and maintain, designed with practicality and user-friendliness in mind.