Product Parameters:

- Power supply: 110V/220V AC 60HZ/50HZ

- Dimensions: L1200*W900*H1500MM

- Weight: 200KG

- Power: 450W

- Air pressure: 4-6kg/cm²

Product Description:

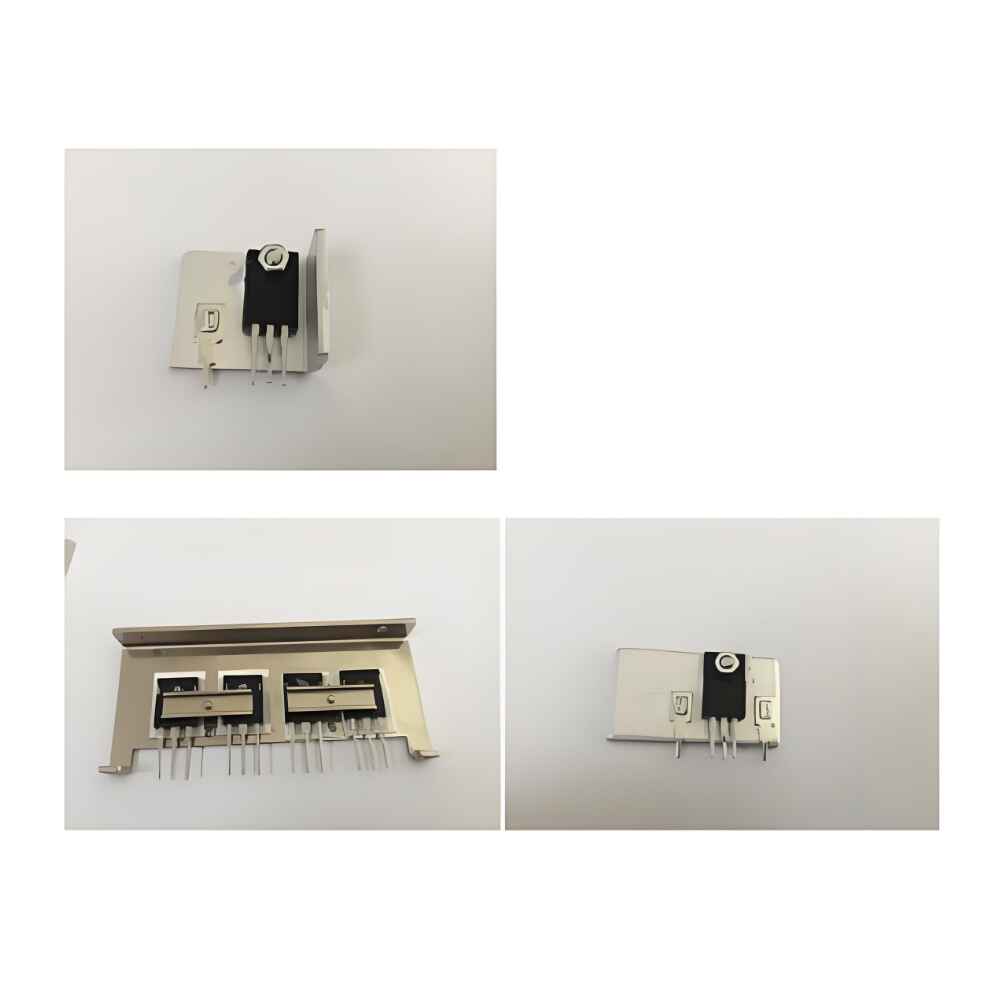

- The equipment is a dedicated screw fastening machine for automatic heatsink assembly and transistor (MOSFET) locking.

- The system operates based on a rotary turntable principle, with each action performed at specific workstations. The operator places the heatsink onto the fixture, and the MOSFET transistors are automatically arranged. The system features automatic feeding, lead trimming, molding, and thermal grease application. The components are then automatically grabbed and positioned onto the heatsink, followed by automatic screw fastening. Multiple MOSFET transistors can be locked onto a single heatsink at different workstations, and the completed products are sent out through a small conveyor system. This cycle repeats automatically.

- All screw fastening actions are fully automated, and the specifications of the heatsinks can be adjusted by changing molds. The number of MOSFET transistors locked onto each heatsink can be increased or decreased, with the standard configuration accommodating up to three workstations. For more, custom solutions are available.

- The equipment uses Mitsubishi PLC control and a user-friendly touch screen interface for operation. The system is highly stable with low defect rates, thanks to the use of divider positioning. The high level of automation allows it to replace multiple operators and is widely used in power supply production factories.