FL-108 Type No-Waste Jumper Wire K-Forming Machine

Overview

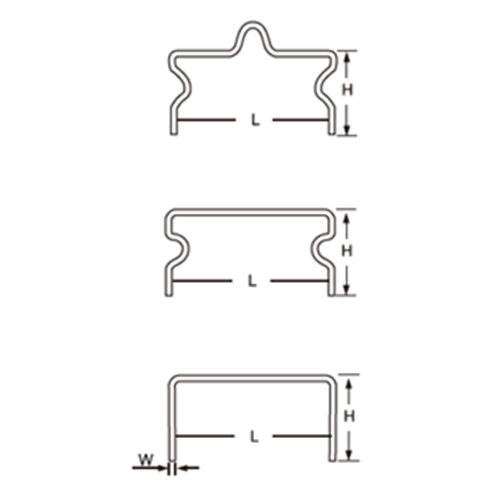

The machine uses Mitsubishi PLC control for fully automated operation, requiring no manual intervention during the processing. With high stability, it can form various complex jumper wire shapes, such as K-shaped, V-shaped, angled, arc, and other customized non-standard shapes through mold customization. This makes the machine highly versatile and suitable for a wide range of applications.

parameter

- Power: 110V/220V AC 60Hz/50Hz

- Dimensions: L650W420H420mm

- Speed: 2500-3600 pcs/h

- Weight: 50kg

- Power: 60W

- Air Pressure: 4-6 kg/cm²

feature

Mitsubishi PLC Control: The machine features fully automated operation with no manual intervention required during the processing, ensuring high stability throughout the entire operation.

Computer-HMI Touchscreen Control: Parameters such as wire length, lead length, and production output can be easily set on the human-machine interface (HMI) touchscreen. The machine is designed for user convenience with infinite automatic shutdown for enhanced safety.

The machine can form various complex jumper wire shapes, including K-shape, V-shape, angled, arc, and other customized non-standard shapes through mold customization.

Wide Versatility: The pitch can be adjusted from 5-65mm without changing molds, saving on mold development costs.

Stable Performance: Ensures high forming accuracy, producing smooth and flat jumper wires with no arching, guaranteeing quality assurance.

Energy-Efficient and Eco-Friendly: The machine operates with high processing efficiency, reaching up to 4000 pcs/h, making it 20-40 times faster than manual operation.

Customizable Molds: The machine can also accommodate non-standard special requirements, with the ability to customize molds for unique processing needs.

Durable Materials: Both cutting tools and molds are made from Japan-imported steel, ensuring a long service life.