- Blog

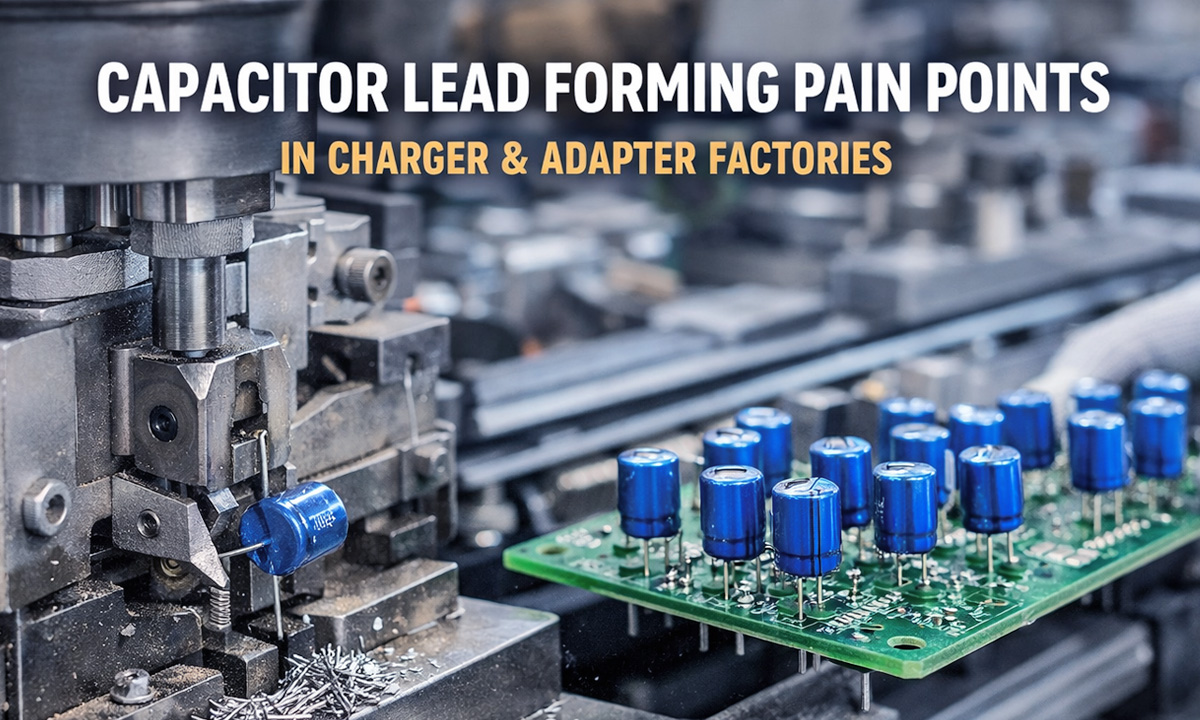

Capacitor Lead Forming Pain Points in Charger & Adapter Factories

- By tian81259@gmail.com

Charger and power adapter factories live and die by throughput and solder quality. You can have great SMT, clean wave solder profiles, and solid ICT—then lose yield because a “simple” through-hole capacitor doesn’t sit flat, pitches don’t match, or leads crack during forming. In high-volume charger/adaptor production, capacitor lead forming is one of those hidden bottlenecks that quietly creates rework, line stoppages, and long-term reliability risks.

Below are the most common capacitor forming pain points we see in charger/adapter plants—and what to do about them.

1) Lead pitch doesn’t match PCB holes (mis-insertion, tilted parts, bent pins)

What it looks like on the line

- Capacitors “fight” the holes during insertion

- Operators bend leads by hand to make them fit

- Parts sit tilted, or can’t sit flush on the board

Why it happens

- Pitch tolerance is drifting (tool wear, inconsistent feeding, operator setting differences)

- Mixed capacitor suppliers (same nominal pitch, different body/lead geometry)

- PCB hole tolerance + solder mask constraints reduce real insertion window

Impact

- Insertion slows down (or automation jams)

- Wave solder defects increase due to poor seating and inconsistent lead protrusion

- Higher risk of lifted pads when operators force components

Fix

- Lock your target pitch and tolerance (per capacitor family) and verify with go/no-go gauges

- Use dedicated tooling / quick-change setup per pitch to avoid “one setting fits all”

- If your product mix is heavy, consider equipment designed for stable pitch control and repeatability: Capacitor Lead Forming Machines

2) Cut length inconsistency (solder quality problems + cosmetic defects)

What it looks like

- Some boards have leads too long → risk shorts, poor clearance, ugly solder tails

- Some leads too short → weak solder joints, insufficient fillet, pull-test failures

- AOI flags “lead protrusion out of spec”

Why it happens

- Manual cutting or semi-auto setups rely on operator feel

- Knife wear, misalignment, or inconsistent lead positioning before cutting

- Capacitors arrive with variable lead straightness

Impact

- Wave solder variability (bridging, icicles, insufficient solder)

- More touch-up and rework, especially on dense charger boards

- Higher scrap risk after functional test if joints are marginal

Fix

- Define a cut-length spec tied to your soldering method (wave vs selective)

- Add a simple in-line check: lead protrusion sampling every X boards (or shift)

- For a deeper selection checklist, use this guide: 5 Must-Consider Factors When Choosing a Capacitor Lead Forming Machine (2026)

3) Lead cracks / micro-fractures after forming (field failures you don’t see today)

What it looks like

- Leads break during insertion or after wave solder

- “Intermittent” failures after vibration/thermal cycling

- Returns that don’t reproduce easily in the factory

Why it happens

- Over-bending radius (too tight) or wrong forming sequence

- Excessive mechanical stress from misfeeds or double forming

- Harder lead material or plating differences across suppliers

Impact

- Reliability risk (especially in higher-power adapters that run warm)

- Hidden cost: warranty + brand damage

Fix

- Use proper bend radius and avoid re-bending formed leads

- Reduce forming stress by ensuring consistent lead straightening before bend

- Standardize per capacitor type (electrolytic vs film, lead diameter, temper)

4) Low consistency across shifts (same product, different results)

What it looks like

- Day shift runs fine; night shift shows more insertion issues

- Different operators “tune” the same machine differently

- Setup drift after tool changes or maintenance

Why it happens

- No documented forming parameters (pitch, cut length, stand-off height)

- Setup relies on tribal knowledge

- Tooling wear isn’t tracked

Impact

- Quality escapes, unstable yield, extra rework manpower

- Hard to scale production without adding headcount

Fix

- Build a simple forming spec sheet per SKU family:

- Target pitch + tolerance

- Cut length (min/max)

- Stand-off height requirement

- Acceptable lead angle/parallelism

- Add tool-life tracking (knife, bending die) and planned replacement

5) Frequent changeovers due to high SKU mix (lost OEE)

Charger/adaptor plants often run many models and variants (different wattages, plugs, certifications). That usually means many capacitor specs, too.

Pain

- Changeover takes too long

- Wrong tooling used → immediate quality drift

- “Small” mistakes snowball into a whole pallet of rework

Fix

- Standardize capacitor families across designs when possible

- Use quick-change tooling and visual Poka-Yoke labels per pitch/lead diameter

- Keep pre-set tooling kits for top-running SKUs

6) Feeding and alignment issues (jams, bent leads, downtime)

What it looks like

- Leads get scratched, twisted, or bent before forming

- Jams during feeding cause stop-start production

- More burrs after cutting

Why it happens

- Capacitors aren’t straight or leads are tangled in bulk handling

- Incorrect guide/track settings for lead diameter or body size

- Build-up of debris near knives and dies

Fix

- Improve pre-alignment/straightening and debris control (cleaning intervals)

- Match guides to lead diameter and body size (don’t “run loose”)

Practical “Factory Checklist” for Better Capacitor Forming (Charger/Adapter Lines)

- Define spec: pitch, cut length, stand-off height, tolerances

- Control setup: documented parameters + quick verification gauges

- Reduce stress: correct bend radius and avoid rework bending

- Track tooling wear: knives/dies with planned replacement

- Stabilize feeding: alignment, guides, cleaning schedule

- Measure the right KPI: insertion issues, AOI rejects, solder defects, rework minutes

If you’re comparing equipment options or want to see proven configurations used in high-volume power electronics production, start here: Capacitor Lead Forming Machines. For machine selection logic and what specs truly matter, read: 5 Must-Consider Factors When Choosing a Capacitor Lead Forming Machine (2026).

Quick CTA

If you tell us your capacitor type (electrolytic/film), lead diameter, target pitch, and required cut length, you can usually narrow down the right forming method fast and avoid the most common yield killers.

Related Posts

20 Years of Expertise, Trusted by Clients Worldwide

The Preferred Choice of Foxconn, BYD, and Huawei