- Blog

Essential Equipment List for Resistor Lead Cutting and Forming

- By tian81259@gmail.com

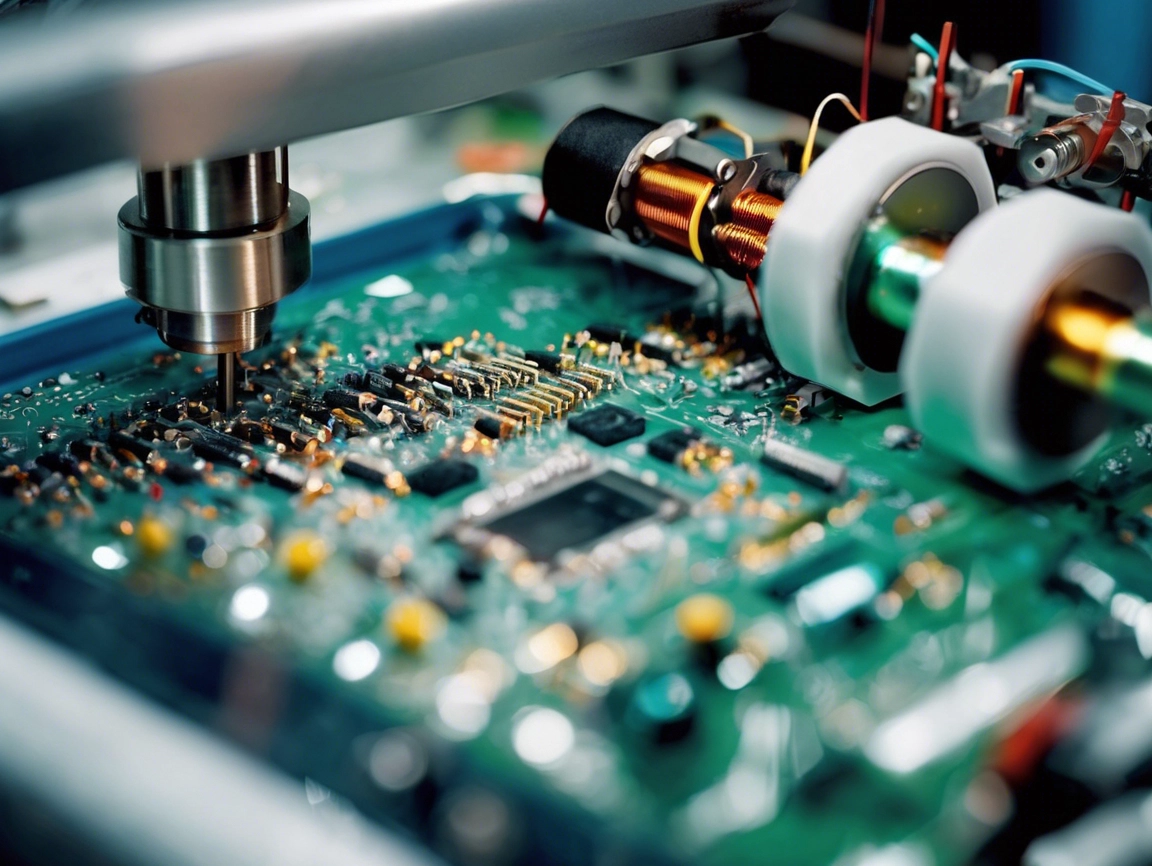

In modern electronics manufacturing, resistors are ubiquitous as fundamental components. The resistor leads not only affect the performance of the resistor but also directly impact its installation and operational efficiency. To ensure the stability and high performance of resistors, precise lead forming is crucial. This article will delve into the equipment required for resistor lead forming and the critical role these devices play throughout the production process.

What is Resistor Lead Forming?

Resistor lead forming refers to the process of bending, controlling the bending angle, and adjusting the position of the resistor leads through mechanized and automated equipment during the production process. This ensures that the leads are securely connected to the resistor body. Lead forming not only improves production efficiency but also ensures product quality. Precision lead forming is especially essential in the manufacturing of high-accuracy resistors, where it is indispensable for achieving the required standards.

What Equipment is Used for Resistor Lead Forming?

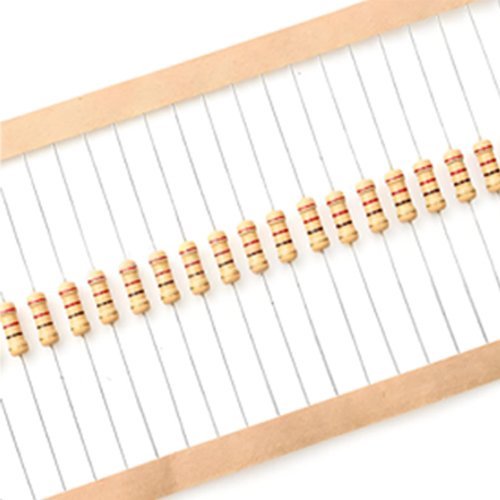

Resistor components typically come in two types of materials: bulk resistors and tape-mounted resistors. Resistor shapes can be classified into vertical resistors and horizontal resistors. Using resistor lead forming and cutting equipment, the resistor leads are shaped according to the resistor’s size, power, and final application requirements (such as axial or radial). The forming machine, equipped with precision molds (blades) and feeding mechanisms, accurately bends the cut straight leads into the desired shape (e.g., common “U” shapes, “90°” bends, or specific angles). The leads are then cut and formed to the preset precise length. The key factors are high precision, smooth and burr-free cutting edges to avoid affecting subsequent forming and soldering. This leads to the development of various resistor forming equipment.

1.Tape-mounted Resistor Forming Machine

Applicable Scope: This machine is specifically designed for forming and lead cutting of tape-mounted resistors, diodes, and other axial components.

Machine Features: The forming and lead cutting can be completed sequentially. The length and pitch of the formed leads can be freely adjusted, offering strong processing capability.

Forming Shapes: U-shape (horizontal), F-shape (vertical), and S-shape (specifically designed for horizontal components with small pitch).

2.Horizontal Resistor Forming Machine

Applicable Scope: Suitable for horizontal forming (such as K-shape or flat-shaped) and lead cutting of bulk resistors, tape-mounted resistors, diodes, and other axial components.

Machine Features: Forming and lead cutting can be completed sequentially. Molds can be customized according to requirements, enabling the processing of any desired shapes.

Forming Shapes: U-shape, K-shape.

3.Vertical Resistor Forming Machine

Applicable Scope: Suitable for horizontal forming (such as K-shape or flat-shaped) and lead cutting of bulk resistors, tape-mounted resistors, diodes, and other axial components.

Machine Features: Forming and lead cutting can be completed sequentially. Molds can be customized according to requirements, enabling the processing of any desired shapes.

Forming Shapes: F-shape, K-shape.

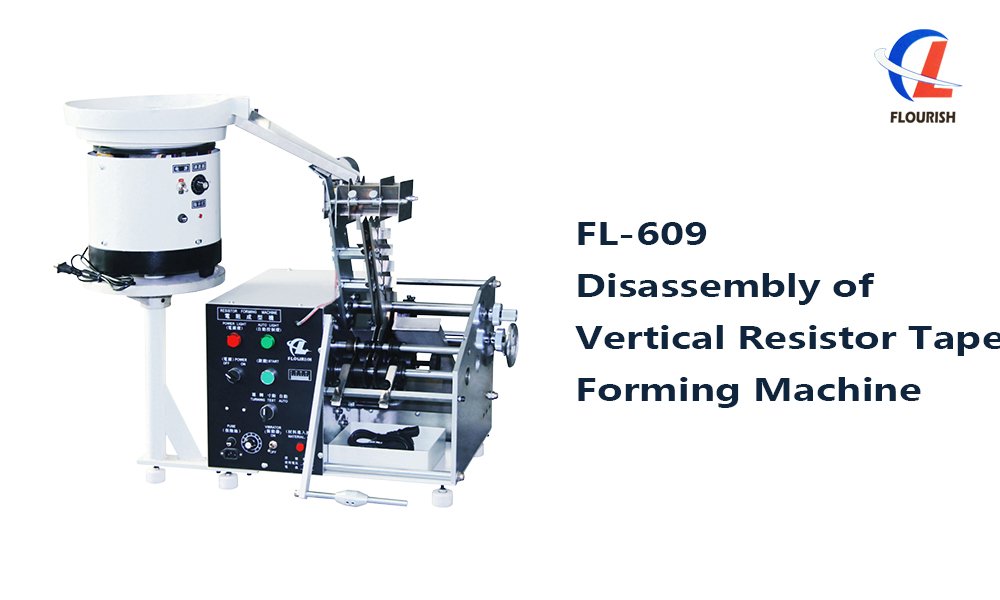

4.Disassembly of Vertical Resistor Tape Forming Machine

Applicable Scope: Suitable for horizontal forming (such as K-shape or flat-shaped) and lead cutting of bulk resistors, tape-mounted resistors, diodes, and other axial components.

Machine Features: This machine is designed to address issues with vertical resistor tape-mounted components, where lead length is insufficient after forming, or for components that require additional sleeves or magnetic beads.

Forming Shapes: U-shape, F-shape, K-shape.

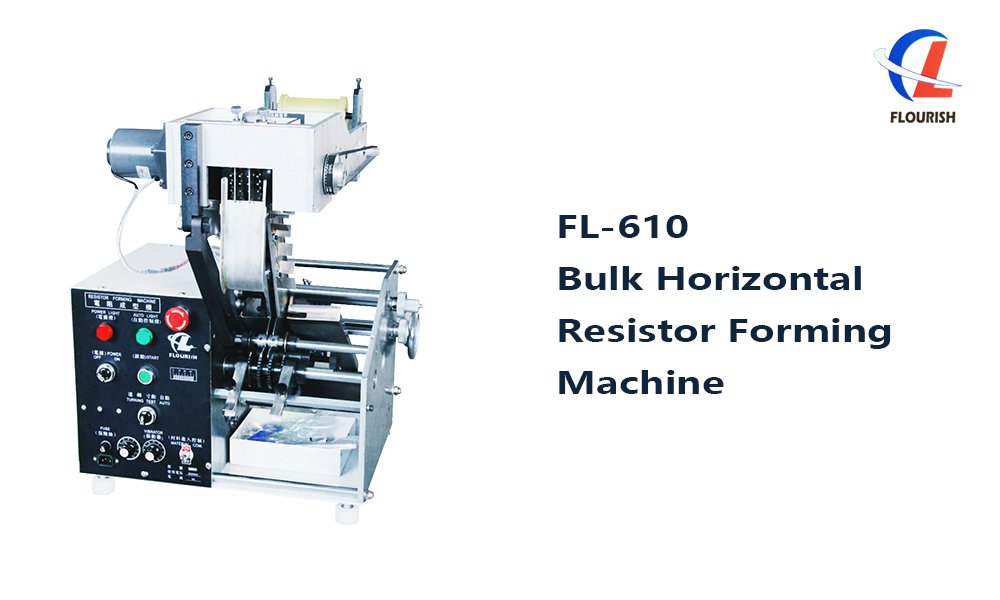

5.Bulk Horizontal Resistor Forming Machine

Applicable Scope: Suitable for horizontal forming and lead cutting of bulk resistors, diodes, and other axial components.

Machine Features: Forming and lead cutting can be completed sequentially. Ideal for large-scale production with stable quality requirements.

Forming Shapes: F-shape, K-shape.

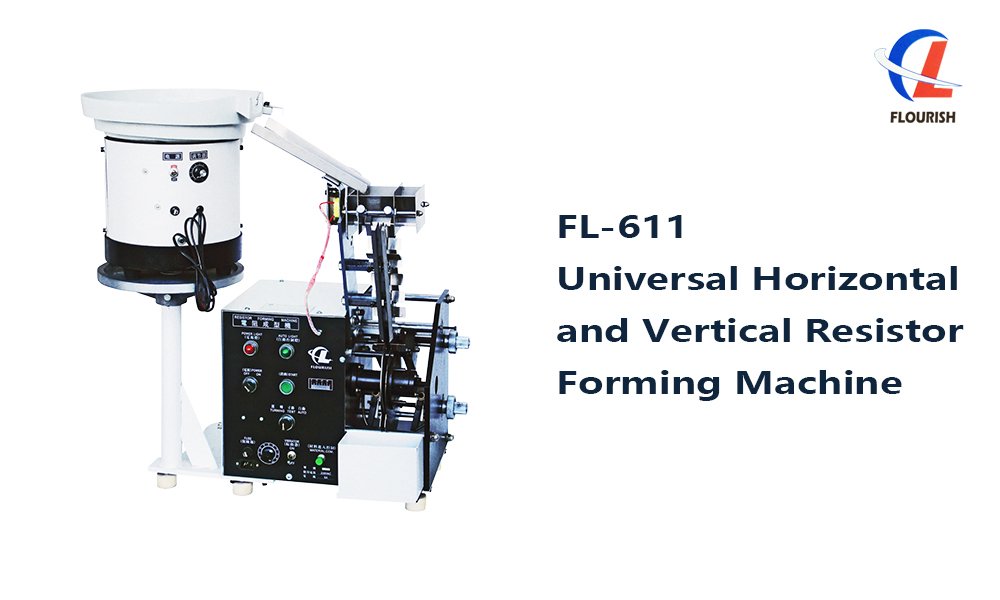

6.Universal Horizontal and Vertical Resistor Forming Machine

Applicable Scope: Suitable for bulk and tape-mounted carbon film resistors, metal film resistors, and diodes. This is currently the most advanced model for lead forming and cutting.

Machine Features: With a multifunctional design, it allows easy conversion between horizontal and vertical forming by simply changing molds. The machine offers high processing accuracy, with lead cutting and pitch precision within a ±0.1mm range.

Forming Shapes: U-shape, F-shape, K-shape.

7.Resistor Forming and Automatic Soldering Equipment

Machine Features:

- The equipment operates automatically with the following workflow: manually loading resistors → automatic lead cutting and feeding → lead bending → lead soldering → lead re-bending → unloading, and this process repeats.

- The equipment speed is adjustable, with a maximum capacity of 2500-3000PCS/H, offering the best processing efficiency in its category.

- The equipment uses a workstation design, allowing each mechanism to be individually adjusted. It is easy to operate, flexible, and highly safe.

- The design is compact, space-saving, and efficient.

Forming Shapes: U-shape, F-shape, K-shape.

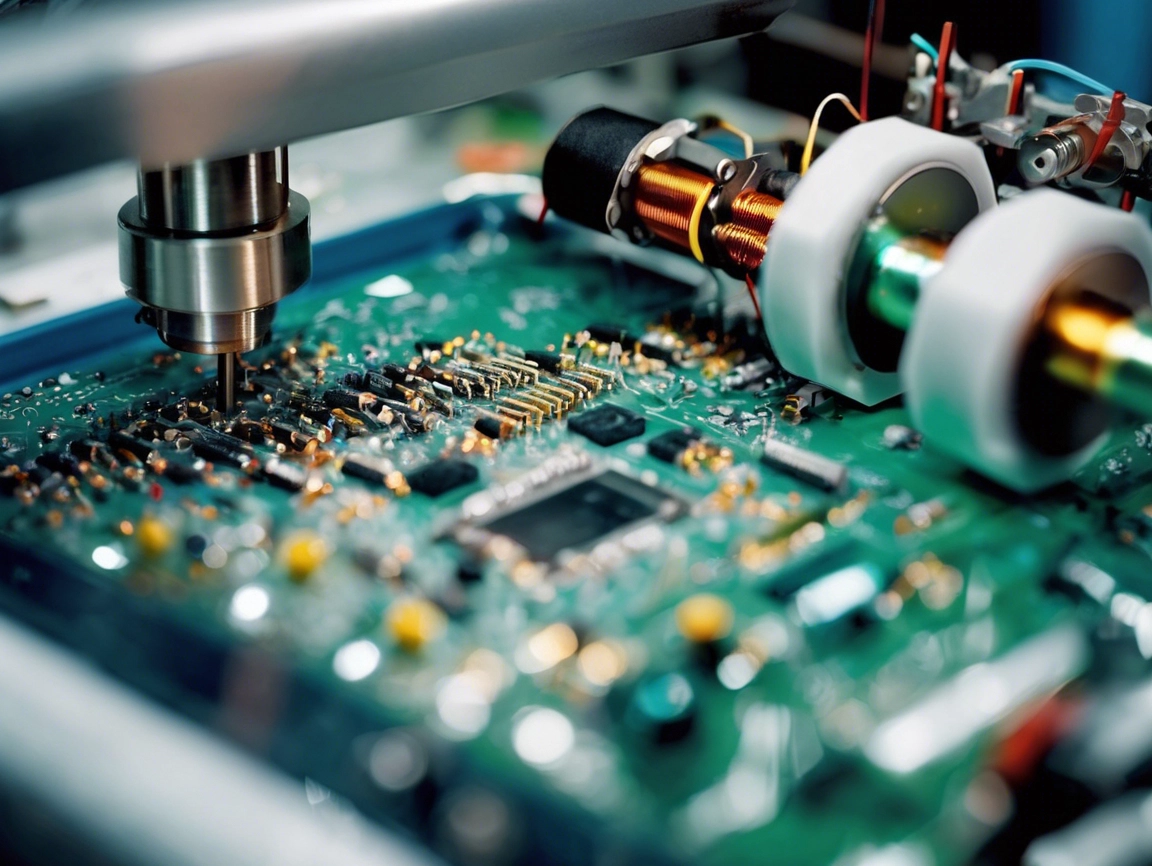

The equipment used in the resistor lead forming process is crucial to the efficiency and quality of the entire production process. These devices enhance operational efficiency, ensure the stability and consistency of resistor forming, and help factory owners save on labor costs while reducing material waste during production. They are undoubtedly powerful tools that can support enterprise production.

The resistor lead forming and cutting solutions provided by our company, through precise control technology and automated equipment, meet the demands of various electronic component production, offering high-quality, high-efficiency production support to our customers.

Related Posts

20 Years of Expertise, Trusted by Clients Worldwide

The Preferred Choice of Foxconn, BYD, and Huawei