- Blog

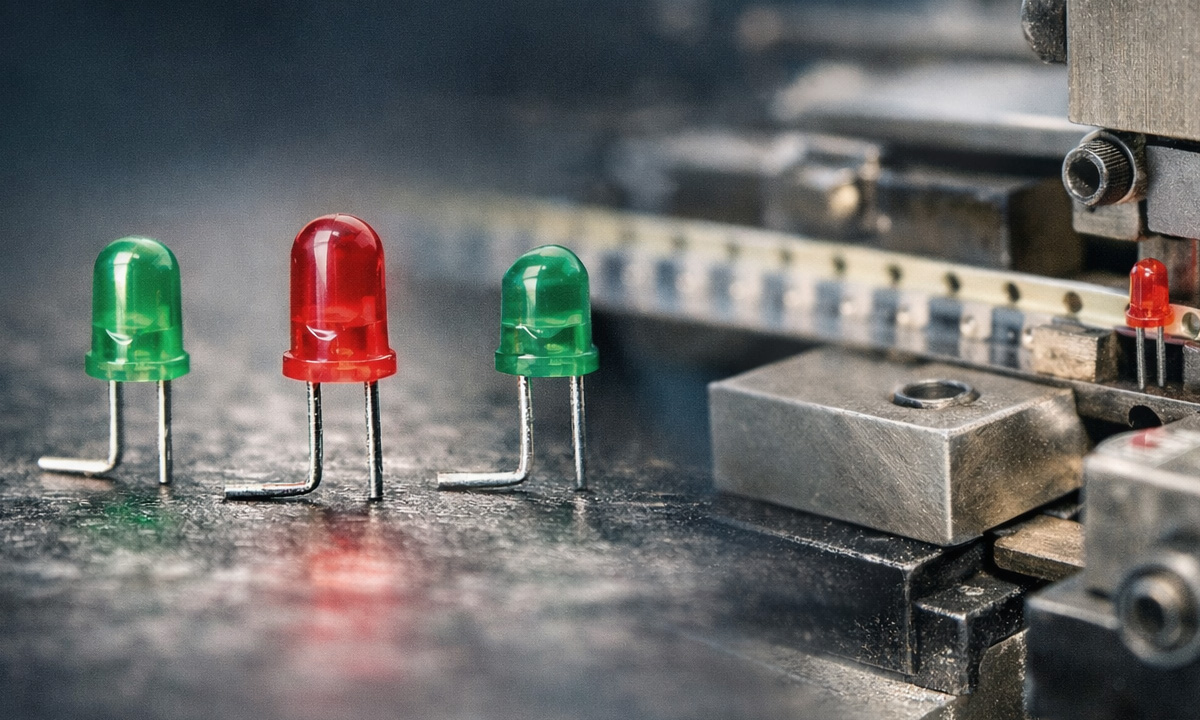

LED Lead Length Inconsistency After Forming: Causes, Troubleshooting, and Fixes

- By tian81259@gmail.com

When LEDs (especially radial through-hole LEDs) come off the lead cutting/forming process with inconsistent lead length, it’s more than a cosmetic issue. It can quickly create:

- Insertion problems (won’t seat evenly, jigs jam, auto-insertion misfeeds)

- Soldering risk (unstable solder fill in wave/selective soldering → cold joints/bridging)

- Yield loss (inconsistent standoff height, uneven assembly fit, rework and scrap)

Below is a shop-floor friendly, step-by-step way to diagnose and solve it—fast.

1) First: Identify Which “Inconsistency” You Actually Have

Before adjusting the machine, confirm what’s drifting:

A. Cut Length Variation (after cutting, before bending)

Bending looks fine, but the cut lead length fluctuates.

Typical signs: lead ends vary randomly; left/right legs may drift; variation increases over a long run.

B. Forming Reference Drift (bend point moves)

The cut looks acceptable, but the bend position / bend datum shifts, so the final exposed length changes.

Typical signs: insertion depth changes; lead span and bend angle occasionally shift.

C. Feeding / Positioning Instability (the part doesn’t seat consistently)

The LED enters the tooling with inconsistent posture or stop position, so both cut and bend fluctuate.

Typical signs: first few hundred pcs are good, then drift; or a new reel/bag immediately changes the results.

10-minute isolation test:

Measure 30 pcs in two stages:

- After cutting only (no forming) → checks cut length stability

- After forming → checks bend datum and posture stability

This quickly tells you where the variation starts.

2) Troubleshooting Checklist (Start Easy, Then Go Deeper)

Step 1 — Confirm Measurement Method (this is a common trap)

- Use a consistent datum: LED body bottom to lead tip or bend point to lead tip (don’t mix)

- Use one tool consistently: calipers vs. go/no-go gauge

- Standardize operator technique (excess force can deflect thin leads)

If different operators get different numbers, fix the SOP first—then tune the machine.

Step 2 — Check the Material (you can’t “tune out” poor consistency)

Especially after a supplier/batch change, inspect:

- Lead straightness (pre-bent/warped leads won’t stop consistently)

- Lead diameter tolerance (affects shear force and springback)

- LED body bottom flash/gate marks (affects seating/stop datum)

- Tape packaging pitch and hole accuracy (major for tape-fed setups)

Quick verification: run 100 pcs from a “known good” batch.

If it stabilizes immediately, the root cause is likely material/packaging variation.

Step 3 — Feeding & Stop Position (where most inconsistency begins)

Common causes and fixes:

- Loose guide rail / stop block hardware → re-align and lock down

- Excess vibration before the cutting zone → reduce vibration and stabilize feed

- Clamp pressure inconsistent → too tight = deform; too loose = slip

- Tape pitch mismatch (12.7 mm vs 15 mm) → creates periodic variation

Speed test: drop speed to ~70% and recheck.

If variation shrinks, you’re dealing with dynamic stability/feeding posture.

Step 4 — Blade and Tooling Wear (wear = drift)

Watch for:

- Burrs, stringing, rough cut edges

- Increasing noise/vibration during cutting

- “Gets worse over time” within a shift

Fix actions:

- Clean chips/debris around the shear area (debris shifts the datum)

- Inspect blade edge for dulling/chipping; sharpen/replace as needed

- Check tooling clearance, worn dowel pins, weak return springs

Step 5 — Air Supply / Stroke / Sensors (critical for pneumatic systems)

- Air pressure fluctuation (shared air line, moisture, unstable regulator)

- Stroke stop nuts drifting or not locked

- Sensor/limit switch position creeping

Quick check: stabilize the air supply and rerun a short lot.

If drift disappears, the root cause is likely pneumatic stability or stroke control.

3) Fix It by Scenario (Practical, Direct Actions)

Scenario A — Mostly Cut Length Variation

Do these first:

- Re-verify and lock the stop datum (stop block/locator)

- Clean and inspect the blade edge (burrs and chips matter)

- Validate stability at a lower speed, then ramp up to find a stable ceiling

If you’re running bulk radial parts and want better length stability, consider a dedicated cutting solution such as:

- FL-803 Automatic Bulk Capacitor Lead Cutting Machine (often used for radial parts like LEDs)

https://flourishe.net/product/fl-803-automatic-bulk-capacitor-lead-cutting-machine/

Scenario B — Mostly “After Forming” Drift (bend point / datum shifts)

Prioritize:

- Evaluate springback variability (lead diameter/material variation + speed effects)

- Check clamp blocks for wear that causes slip during bending

- Confirm stroke limits are locked (especially pneumatic setups)

- Add simple in-process checks: first-article + hourly sampling

For radial forming applications, a typical forming solution is:

- FL-810 Pneumatic Bulk Capacitor Forming Machine (commonly used for radial forming scenarios)

https://flourishe.net/product/fl-810-pneumatic-bulk-capacitor-forming-machine/

Scenario C — Tape-Fed LEDs With Periodic Variation

This is usually pitch/hole positioning/tension related. Confirm:

- Your tape standard: 12.7 mm vs 15 mm

- Feed wheel / indexing pin compatibility

- Tape tension control (tension swings = length swings)

For tape-fed radial component cutting, consider:

- FL-816 Tape-fed Radial Component Lead Cutting Machine

https://flourishe.net/product/fl-816-tape-fed-radial-component-lead-cutting-machine/

4) Prevent It From Coming Back: Turn “Consistency” Into a Controlled KPI

Process controls

- Fixed operating speed range

- Air pressure range + moisture control

- Blade/tooling maintenance interval (counts or shift-based checks)

Quality controls

- Target cut length + tolerance

- Left/right lead difference (if required)

- Burr/deformation criteria

- Bend angle and lead span (for insertion stability)

Gauging

- A simple go/no-go lead length gauge (fast, consistent)

- A bend angle reference sample board for shift handoff

5) Suggested Internal Link for “Next Step” (Conversion-Friendly)

If you want this post to naturally funnel readers into equipment selection, add a “Choose the Right Machine” link:

- Radial Lead Forming Machines Collection

https://flourishe.net/proudt/electronic-component-lead-forming-machine/radial-lead-forming-machines/

This keeps the article helpful while giving visitors an obvious next action.

FAQ

Q1: What tolerance should we target for LED lead length after forming?

Always follow the customer drawing/spec. In practice, the fastest way to control this is: define a clear datum + use a go/no-go gauge to reduce operator measurement variation.

Q2: Why does it look fine at the start, then drift later?

Most commonly: chips build up near the shear zone, hardware loosens slightly, vibration changes at higher speed, or air pressure fluctuates. Start with cleaning + stop datum recheck + air stability.

Q3: We changed LED suppliers and the variation got worse—what now?

Confirm lead straightness, diameter tolerance, and (for tape) pitch/hole accuracy before chasing machine settings. Material inconsistency will overwhelm a stable setup.

Related Posts

20 Years of Expertise, Trusted by Clients Worldwide

The Preferred Choice of Foxconn, BYD, and Huawei