- Blog

Manual Lead Forming Machine | Affordable Lead Cutting & Bending Tool for Electronics

- By tian81259@gmail.com

Efficiency and Precision: The Dual Pursuit in Electronics Manufacturing

In the electronics manufacturing industry, efficiency and precision are the eternal goals. While fully automated equipment has become the mainstream in large-scale production, the manual lead forming machine continues to play an irreplaceable role thanks to its flexibility, cost-effectiveness, and accuracy.

Whether in R&D prototyping, small-batch production, or component repair and rework, this tool remains an indispensable asset.

What is a Manual Lead Forming Machine?

A manual lead forming machine is a specialized tool designed to cut and bend the leads of electronic components such as resistors, capacitors, diodes, and ICs.

Manual lead forming machine parameters:

| type | parameter |

|---|---|

| Voltage | AC220V 50Hz/60Hz |

| power |

25W

|

| efficiency |

0-43000PCS/H

|

| size |

L420mm*W230mm*H270mm

|

| weight |

22KGS

|

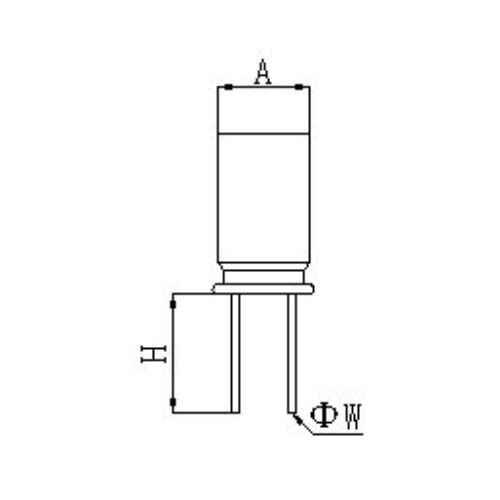

Molded parts specifications:

| H | Foot length |

3-20mm

|

| A | Component size |

3-20mm

|

| W | Lead diameter |

0.4-1.0mm

|

Operators place the component into a dedicated mold, then press the handle to drive the cutting and forming mechanism. In a single step, the leads are trimmed to the desired length and bent into specific shapes—such as 90-degree vertical insertion or gull-wing surface mount.

The core advantage lies in human control: every operation can be instantly adjusted and confirmed, making it the perfect solution for diverse, non-standardized processing needs.

Key Advantages and Application Scenarios

1. Exceptional Flexibility & Adaptability

-

Scenario: R&D, laboratories, sample making.

-

Advantage: One base machine with multiple molds can handle nearly all through-hole components without complex programming. Simply switch molds to meet new requirements.

2. Outstanding Cost-Effectiveness

-

Scenario: Small and medium-sized enterprises, repair shops, training schools.

-

Advantage: Affordable price, simple structure, and minimal maintenance costs. A high ROI solution compared to expensive automation equipment.

3. Superior Precision & Consistency

-

Scenario: Components with strict requirements for lead length and forming angle.

-

Advantage: Precision molds and guiding structures ensure consistent cutting and forming results, avoiding errors from manual pliers and improving soldering reliability.

4. Easy Operation & Labor Saving

-

Scenario: Operators with limited technical training.

-

Advantage: Simple handle operation completes both cutting and forming in one stroke—faster and easier than pliers, significantly reducing labor intensity.

How to Properly Operate a Manual Lead Forming Machine

-

Choose the mold – Select the right mold based on package type and forming requirements.

-

Adjust positioning – Some models allow fine-tuning of lead length. Test with samples before production.

-

Place the component – Insert the component into the mold slot, ensuring leads are properly seated.

-

Operate the handle – Press the handle smoothly until you hear the cutting sound.

-

Retrieve the component – Release the handle and remove the finished component.

Buying Guide: What to Look for in a Manual Lead Forming Machine

-

Processing range: Ensure it supports your component types (e.g., SOIC, DIP, QFP) and pin pitch.

-

Mold options: Check included molds, availability, and cost of additional molds.

-

Build quality: A solid frame prevents wobbling; high-grade tool steel molds ensure durability and precision.

-

Safety features: Protective design helps reduce the risk of injury.

Conclusion

The manual lead forming machine may not be the flashiest star on the production line, but it is the most reliable and economical craftsman’s tool. It perfectly bridges the gap between full automation and hand tools, ensuring quality, protecting components, and improving cost efficiency.

👉 If you are looking for a practical solution for small-batch, multi-variety, high-precision component processing, investing in a high-quality manual lead forming machine is undoubtedly a smart decision.

Contact us today to find the best model and mold configuration for your needs.

Related Posts

20 Years of Expertise, Trusted by Clients Worldwide

The Preferred Choice of Foxconn, BYD, and Huawei