- Industry News

Maximizing Efficiency in IGBT Heatsink Installation

- By tian81259@gmail.com

The semiconductor industry is undergoing an unprecedented wave of automation upgrades. As chip complexity increases, production capacity demands soar, and stringent product consistency requirements are set, traditional manual assembly methods can no longer keep up. Automated assembly lines, with their core advantages of over 30% efficiency gains, a 50% reduction in defect rates, and the ability to operate 24/7 with stability, are rapidly becoming industry standards. These developments are driving semiconductor manufacturing into a new era of high precision and reliability.

Semiconductor Assembly Industry: The Irreversible Automation wave

The global semiconductor industry is at a critical stage of smart transformation. The key factors driving automation upgrades include:

Exponentially Increasing Precision Requirements: As chip component sizes move into the micrometer range, the margin for error in manual operations becomes nearly nonexistent.

Cost and Efficiency Pressures: Rising labor costs and the demand for higher production capacities have significantly shortened the return on investment for automation equipment to just 1-2 years.

Yield as a Lifeline: Automotive-grade and industrial-grade chips require defect rates below 0.1%, making consistency a core competitive advantage.

Power Semiconductor Modules: The Core Battlefield for Automation Upgrades

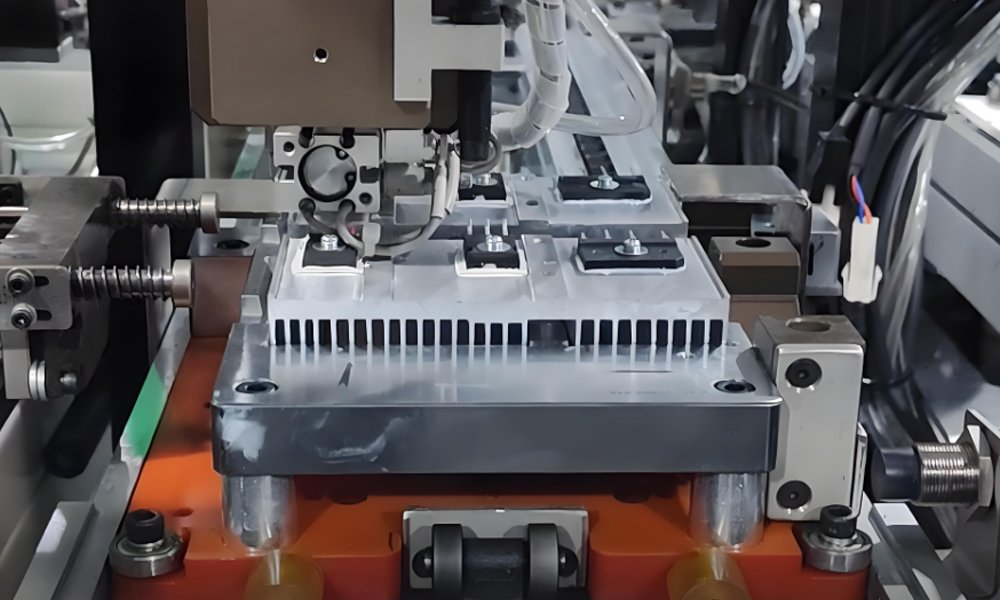

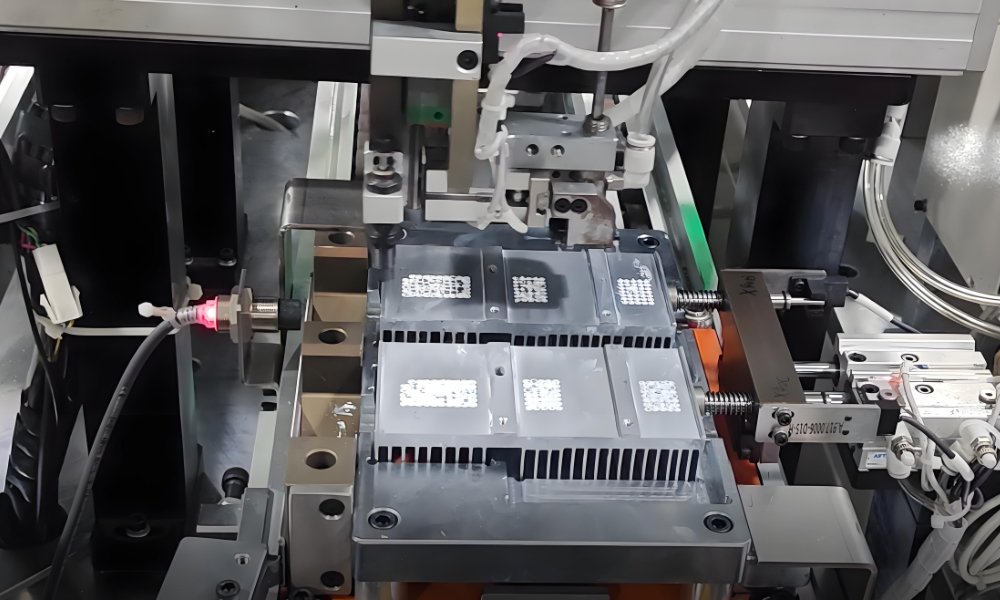

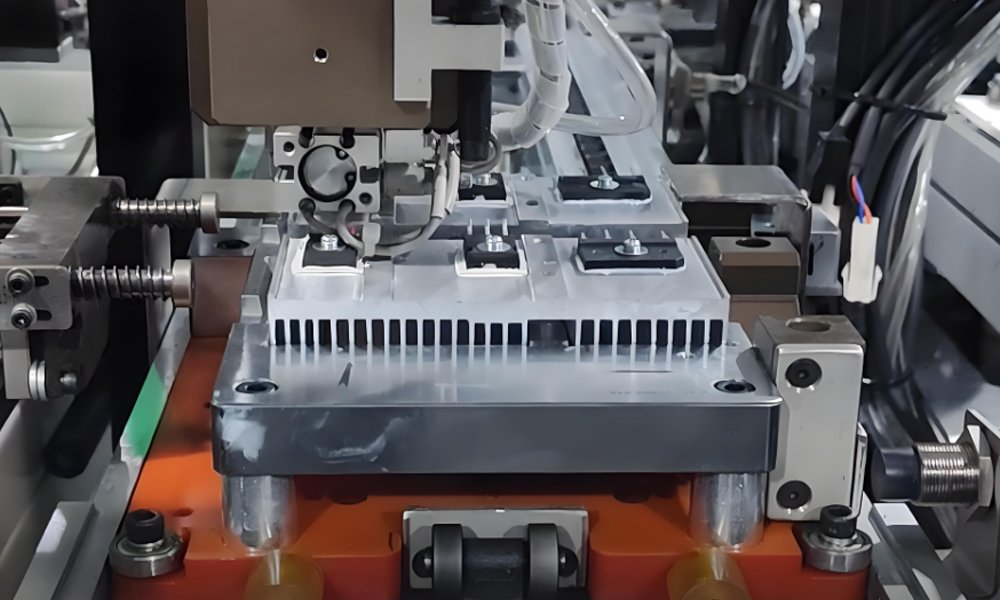

Among the various steps in semiconductor assembly, the screw fastening of IGBT heatsinks is crucial. As the core component of power semiconductors, IGBT devices are widely used in fields such as new energy vehicles, industrial frequency converters, and smart grids. These devices generate a significant amount of heat during operation, and inadequate heat dissipation can severely impact their performance and lifespan. Therefore, the quality of the IGBT heatsink installation directly affects the stability and reliability of the equipment.

Industry Pain Points:

Millimeter-Level Positioning Deviations → 40% reduction in heatsink interface contact area → Increased thermal resistance leading to overheating failure.

Manual Torque Fluctuations ±15% → Uneven stress distribution on interface materials → 50% reduction in thermal cycle life.

No Process Traceability → Failure to trace root causes of faulty modules → Increased warranty costs.

Breaking the Bottleneck: Full Automation for IGBT Heatsink Screw Fastening

To address the ultimate challenge in power module assembly, Shenzhen Flourishe Electronic Technology Co., Ltd. offers a high-precision intelligent screw fastening system that directly tackles industry pain points:

Our transistor lock heat sink equipment has achieved 3 major upgrades

1.Positioning Accuracy: Mechanical fixture errors ±0.5mm → Our solution uses machine vision + AI compensation to achieve positioning accuracy of ±0.02mm.

2.Torque Control Failure: Pneumatic tool fluctuation ±10% → We employ servo electric cylinders with closed-loop control, reducing fluctuations to <±2%.

3.Process Data Black Box: No process records → Our system tracks every screw’s torque-angle curve for full traceability.

For IGBT heatsink screw fastening, our product range provides high-precision positioning to ensure that the IGBT is installed on the heatsink precisely, eliminating issues of poor heat dissipation due to installation deviations. The intelligent torque control technology adjusts the fastening torque based on different IGBT models and heatsink materials, ensuring both secure fastening and protection against over-torque damage. Furthermore, our solutions are highly compatible, adaptable to various IGBT and heatsink types, meeting diverse customer needs. On automated production lines, our solutions seamlessly integrate with other equipment, enabling efficient automated operation of the IGBT heatsink screw fastening process, significantly improving production efficiency and reducing labor costs. For example, a company already using our solution has seen a 30% increase in IGBT heatsink fastening efficiency and a 40% reduction in labor costs.

As the semiconductor industry strives for the “zero defect” ideal and embraces technologies such as heterogeneous integration, the flexibility and intelligence of automated production lines will become critical competitive factors. In this trend, we will continue to innovate, optimizing our products and solutions to provide higher quality, efficiency, and reliability in IGBT heatsink screw fastening. We are committed to helping the semiconductor assembly industry achieve a higher level of automation. In the coming years, as the industry’s automation level deepens, overall production efficiency in semiconductor assembly is expected to increase by over 50%, with defect rates further reduced to below 1%. We will keep pace with industry developments, contributing to this flourishing growth.

Related Posts

20 Years of Expertise, Trusted by Clients Worldwide

The Preferred Choice of Foxconn, BYD, and Huawei