Product Parameters:

- Dimensions: L450 × W260 × H220 mm

- Speed: 40,000 pcs/hour

- Weight: 20 kg

- Power Consumption: 25W

Product Description:

- The equipment features a human-machine interface (HMI) with a Windows-based operating system, enabling high-resolution CCD teaching for easy editing of cutting paths. It allows for single-step modifications and simulation, making programming extremely easy and convenient. The machine can store up to 1000 sets of data, enabling quick retrieval and usage.

- The linear motion axes use AC servo systems, ensuring high cutting precision and accurate positioning, while also optimizing processing speed for efficient operation.

- The machine is equipped with a rotary pneumatic cutter, allowing for the best cutting orientation for each lead, ensuring precision for every component.

- In the inline version, the machine operates with a left-to-right or right-to-left flow sequence for efficient material handling.

- The cut leads are automatically removed via a vacuum system, preventing splashing or leftover leads on the board surface.

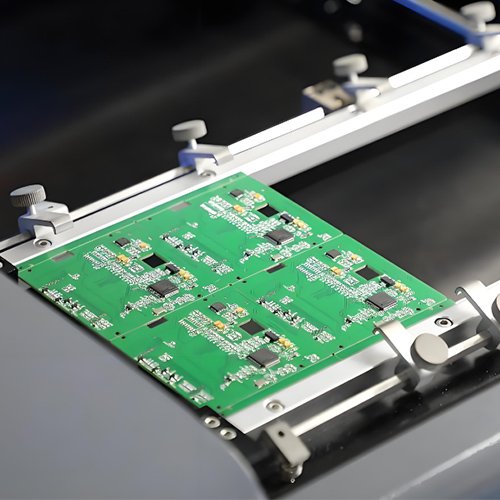

- The conveyor line uses servo motors combined with belt feeding systems, with a standard adjustable width (100–400mm). Custom sizes are available for boards exceeding these dimensions.

- The machine features a unique low-stress design, avoiding any pulling or vibration during the cutting process, which could affect the quality of other PCBA components. For extremely tilted leads, manual adjustment is required before cutting.

- DC53 steel, imported from Japan, is used for the molds and cutting tools, ensuring long service life.

- This machine has been widely applied in multiple customer factories, and its technology is fully matured.

- The metal surface of the equipment is coated with a special paint process, providing corrosion and rust resistance and a scratch-resistant surface.