FL-107 Type Fully Automatic Teflon Tube Jumper Wire Stripping and Forming Machine

Overview

The equipment operates fully automatically, using a Mitsubishi PLC control system and a human-machine interface (HMI) touchscreen. Parameter settings are simple, adjustments are easy, and the machine is designed for easy operation and maintenance.

parameter

- Power: 110V/220V AC 60Hz/50Hz

- Dimensions: L680W450H420mm

- Speed: 2500-3600 pcs/h

- Weight: 50kg

- Power: 200W

- Air Pressure: 4-6 kg/cm²

feature

The equipment is a specialized machine designed for processing coiled Teflon-covered jumper wires, performing cutting, stripping, and forming all in one integrated operation.

Fully automatic operation: The working process includes wire feeding → cutting → stripping both ends → forming, repeating continuously for high efficiency.

Automatic feeding of the entire coil is achieved through the coordination of three imported stepper motors, ensuring fully automated processing. The machine uses an all-mechanical structure, offering high stability and precision.

The equipment is controlled by Mitsubishi PLC with a human-machine interface (HMI) touchscreen, making parameter settings simple, adjustments easy, and ensuring user-friendly operation and maintenance.

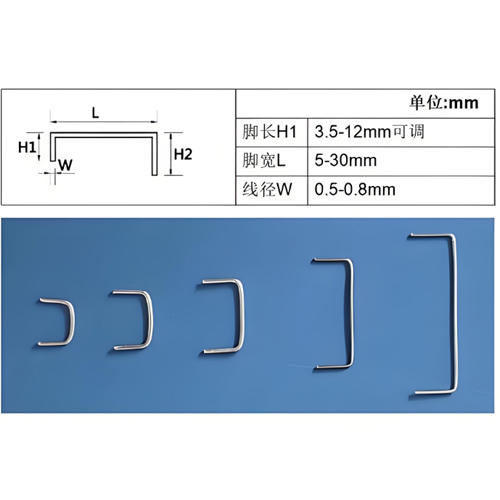

The jumper wire pitch and lead length can be adjusted after processing, providing flexible manufacturing options.

The processed jumper wires and stripped Teflon tubing are fed into two separate discharge ports, facilitating easy collection of finished products.

The equipment offers excellent stability, allowing for unmanned operation after startup. It is widely used in power supply manufacturing factories.