- Blog

Resistor Forming Machine Selection Guide: A Complete Procurement Plan for Efficiency and Precision

- By tian81259@gmail.com

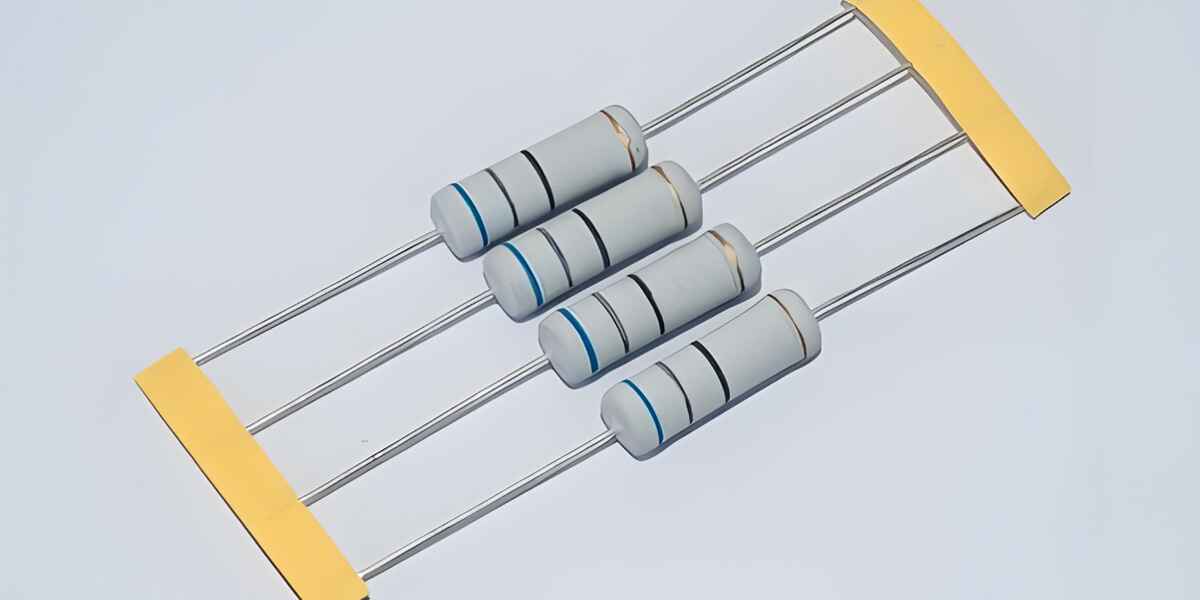

A resistor forming machine is a specialized piece of equipment designed to bend and form the leads of axial components such as resistors, diodes, and capacitors. With the rapid development of automation in the electronics manufacturing industry, the drawbacks of manual lead bending—low efficiency and inconsistent precision—have become increasingly evident. Choosing the right resistor forming machine not only boosts production line efficiency but also ensures product consistency and reliability.

What Is a Resistor Forming Machine?

A Resistor Forming Machine uses molds or cutting tools to trim and bend component leads into specified shapes such as vertical, horizontal, or gull-wing. It is widely used in power adapters, chargers, home appliance control boards, automotive electronics, and other applications, ensuring that components can be smoothly inserted into PCBs and meet process requirements.

Why Is Choosing the Right Resistor Forming Machine Important?

-

Efficiency Boost: Automated forming is 5–10 times faster than manual operation.

-

Precision Assurance: Ensures consistent lead bending, preventing soldering defects and misalignment.

-

Cost Reduction: Lowers long-term labor costs by reducing dependency on manual work.

-

Flexible Adaptability: Supports various lead lengths, bending angles, and forming styles.

Common Types of Resistor Forming Machines

(Comparison table to be inserted here if needed — manual, semi-automatic, fully automatic)

Real Case Study: From Manual to Fully Automatic

A power supply factory in South China used to rely on manual bending, processing only 1,500 resistors per hour with a yield rate below 95%. In 2024, after introducing the FL-621 Fully Automatic Resistor Forming and Welding Machine, output increased to 6,000 units per hour with a yield rate of 98.5%. The investment was recovered within one year.

Price Range & Procurement Recommendations

-

Small factories / R&D departments: Recommended model: FL-805 Belt-Type Radial Capacitor Lead Cutting Machine. Cost-effective and suitable for prototyping and repair.

-

Medium-sized factories: Recommended model: FL-606 Fully Automatic Axial Lead Forming Machine. Balanced efficiency and stability.

-

Large factories: Recommended model: FL-612 High-Precision Resistor Horizontal and Vertical Integrated Forming Machine. Fully integrable with production lines.

Frequently Asked Questions (FAQ)

How much does a resistor forming machine cost?

-

Manual machines: $2,000–$6,000

-

Semi-automatic: $10,000–$30,000

-

Fully automatic: $60,000+ (depending on model and configuration)

Is it worth buying for small-batch production?

Yes. Even a manual machine offers significant efficiency and consistency improvements, making it ideal for R&D labs and small orders.

Can resistor forming machines process other components?

Yes. They are suitable not only for resistors but also for diodes and other axial components.

What is the typical lifespan and maintenance requirement?

5–8 years with proper use. Regular cleaning of cutting tools and guide rails, plus lubrication, ensures long-term stability.

Will you provide on-site training?

Of course, for simple machines, we can easily operate them through remote guidance. For machines that need debugging, we will send engineers to provide on-site services.

Conclusion & Next Steps

Choosing the right resistor forming machine can significantly improve production efficiency and yield rates. 👉 To explore more solutions for electronic component forming, please visit our Solutions Page or contact our engineers directly for selection advice and a detailed quotation.

Related Posts

20 Years of Expertise, Trusted by Clients Worldwide

The Preferred Choice of Foxconn, BYD, and Huawei