- Industry News

Common Resistor Package Sizes: A Practical Guide for Engineers and Buyers

- By tian81259@gmail.com

When you’re laying out a PCB or sourcing components in bulk, “what size is this resistor?” is not a trivial question. Package size affects power rating, heat dissipation, pick-and-place yields, and even whether your automatic lead forming machine can handle the part without cracking the body.

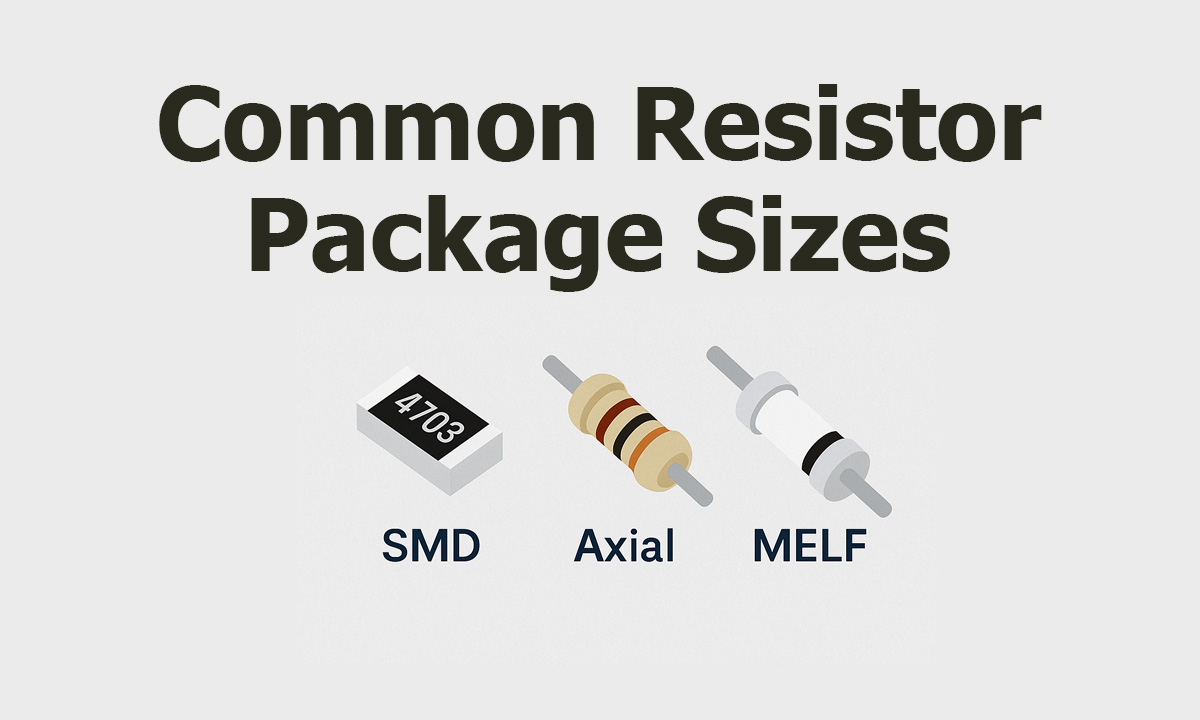

This guide walks through the most common resistor package sizes—SMD, through-hole, and MELF—with dimensions, typical power ratings, and selection tips you can actually use in design and procurement.

1. Why Resistor Package Size Matters

For both engineers and purchasing teams, package size drives several key factors:

- Power rating & temperature rise – Bigger packages can dissipate more heat safely.

- PCB real estate & density – 0402 and 0603 allow ultra-compact layouts; 1206/2512 tolerate more power but eat space.

- Assembly method – High-volume SMT prefers small chip packages; prototypes and high-power boards still use axial (through-hole).

- Mechanical strength & forming – Lead diameter, length and body size affect whether the part survives cutting, bending and insertion on automatic lines.

In other words, you’re not just choosing “0603 vs 0805”; you’re choosing power margin, line capability and long-term reliability.

2. Main Resistor Package Families

2.1 Surface-Mount (SMD) Chip Resistors

Modern designs mostly use rectangular SMD chip resistors standardized by JEDEC / EIA. Their size is encoded by a four-digit number like 0603, which represents length and width in mils (thousandths of an inch): 0.060″ × 0.030″. EEPower

Despite the imperial naming, PCB layout usually uses metric dimensions (mm), so you always see both units in datasheets.

2.2 Through-Hole Axial Resistors

Axial (THT) resistors are still widely used in power supplies, industrial boards and legacy designs. Here, the physical size is mostly tied to power rating—1/8 W, 1/4 W, 1/2 W, 1 W, etc.—and different manufacturers use very similar dimensions. EEPower+1

2.3 MELF Resistors

MELF (Metal Electrode Leadless Face) resistors are cylindrical SMT parts. They offer very good stability and low temperature coefficient but are trickier for pick-and-place because they can “roll”. Typical sizes include MicroMELF, MiniMELF and standard MELF, each with defined length, diameter and power range. EEPower

3. Common SMD Resistor Package Sizes (With Dimensions)

The table below summarizes the most widely used SMD packages, based on JEDEC-style dimensions and typical power ratings compiled from industry references. EEPower

Table 1 – Typical SMD Chip Resistor Package Sizes

| Code (Imperial) | Metric Code | Length (in) | Length (mm) | Width (in) | Width (mm) | Height (mm) | Typical Power Rating* |

|---|---|---|---|---|---|---|---|

| 0201 | 0603 | 0.024 | 0.6 | 0.012 | 0.3 | 0.25 | 1/20 W (0.05 W) |

| 0402 | 1005 | 0.040 | 1.0 | 0.020 | 0.5 | 0.35 | 1/16 W (0.062 W) |

| 0603 | 1608 | 0.060 | 1.55 | 0.030 | 0.85 | 0.45 | 1/10 W (0.10 W) |

| 0805 | 2012 | 0.080 | 2.0 | 0.050 | 1.2 | 0.45 | 1/8 W (0.125 W) |

| 1206 | 3216 | 0.120 | 3.2 | 0.060 | 1.6 | 0.55 | 1/4 W (0.25 W) |

| 1210 | 3225 | 0.120 | 3.2 | 0.100 | 2.5 | 0.55 | 1/2 W (0.50 W) |

| 1812 | 3246 | 0.120 | 3.2 | 0.180 | 4.6 | 0.55 | 1 W |

| 2010 | 5025 | 0.200 | 5.0 | 0.100 | 2.5 | 0.60 | 3/4 W (0.75 W) |

| 2512 | 6332 | 0.250 | 6.3 | 0.120 | 3.2 | 0.60 | 1 W |

*Always check the exact power rating in the manufacturer’s datasheet—values above are typical, not guaranteed.

How to choose between 0402, 0603, 0805 and 1206

- 0402 / 0201 – For ultra-dense, space-critical designs (wearables, mobile). Placement and rework are more demanding.

- 0603 – Good balance of size, power and manufacturability; very common for general-purpose signal lines.

- 0805 – Slightly larger pads, better yield on less-aggressive processes; useful when you want a bit more power margin.

- 1206 / 1210 / 2512 – For higher current and power, or where derating for high ambient temperatures is important (power supplies, LED drivers, automotive).

If you’re new to SMT design, start from 0603 or 0805 unless you’re forced smaller by space or by an existing BOM.

4. Common Through-Hole (Axial) Resistor Sizes

For axial resistors, power rating is the main driver of body size. EEPower’s axial size table gives a good indication of typical dimensions for carbon or metal film resistors: EEPower

Table 2 – Typical Axial Resistor Dimensions vs Power Rating

| Power Rating (W) | Body Length (mm) | Body Diameter (mm) | Lead Length (each side, mm) | Lead Diameter (mm) |

|---|---|---|---|---|

| 1/8 (0.125) | ≈ 3.0 | ≈ 1.8 | ≈ 28 | ≈ 0.45 |

| 1/4 (0.25) | ≈ 6.5 | ≈ 2.5 | ≈ 28 | ≈ 0.60 |

| 1/2 (0.5) | ≈ 8.5 | ≈ 3.2 | ≈ 28 | ≈ 0.60 |

| 1 | ≈ 11 | ≈ 5.0 | ≈ 28 | ≈ 0.80 |

A separate industry reference also links these sizes to typical lead spacing on the PCB, for example: AnyPCBA

- 1/8 W: body ~2.3 mm dia, ~6.5 mm long, lead spacing ≈ 5.08 mm

- 1/4 W: body ~2.5 mm dia, ~7.0 mm long, lead spacing ≈ 7.62 mm

- 1/2 W: body ~3.5 mm dia, ~9.0 mm long, lead spacing ≈ 10.16 mm

- 1 W and above: larger body and similar or slightly wider spacing

Again, exact values vary by manufacturer and resistor type (carbon film, metal film, wire-wound), so always confirm in the datasheet.

Why size matters more for axial resistors

- Power & heat – Higher wattage means a larger surface area for heat dissipation.

- Lead forming & automated insertion – Body diameter and lead diameter directly affect the tooling of your resistor lead forming machine, especially when you’re cutting, bending and inserting thousands of parts per hour.

- Creepage/clearance – High-voltage designs may require larger body-to-lead distances and additional spacing on the PCB.

If you’re running high-volume axial lines, it’s worth standardizing around a few power ratings and sizes that your forming and insertion equipment handle best.

5. MELF Resistor Package Sizes

MELF resistors are cylindrical SMT parts, often used where you need higher stability and better temperature coefficient than typical thick-film chip resistors. EEPower’s MELF overview summarizes three common packages: EEPower

Table 3 – Typical MELF Resistor Package Sizes

| Package Name | Abbreviation | Code | Length (mm) | Diameter (mm) | Power Range (W) |

|---|---|---|---|---|---|

| MicroMELF | MMU | 0102 | 2.2 | 1.1 | 0.2 – 0.3 |

| MiniMELF | MMA | 0204 | 3.6 | 1.4 | 0.25 – 0.4 |

| MELF | MMB | 0207 | 5.8 | 2.2 | 0.4 – 1.0 |

MELF is less common in mainstream consumer designs because:

- It needs special pick-and-place nozzles to avoid rolling.

- Standard 0603/0805 parts are cheaper and easier to handle.

However, in precision, high-stability or high-temperature circuits, MELF can still be the right choice.

6. Package Sizes and Standard Resistor Values (E-Series)

Physical size is only half the story. The actual resistance values available in each package follow standardized E-series value sets defined by IEC 60063 (E6, E12, E24, E48, E96, E192). 维基百科

For example, the E24 series (5% tolerance) uses values like:

1.0, 1.1, 1.2, 1.3, 1.5, 1.6, 1.8, 2.0, 2.2, 2.4, 2.7, 3.0, 3.3, 3.6, 3.9, 4.3, 4.7, 5.1, 5.6, 6.2, 6.8, 7.5, 8.2, 9.1 维基百科

Most SMD and THT resistor families offer a subset of these values, so when you pick a package (say 0603 for 1/10 W), you’ll normally have a standard E24 or E96 value set available in that package.

7. Practical Selection Workflow

When you’re choosing a resistor package size for a real design, a simple, practical workflow is:

- Determine power dissipation

Use P=I2R or P=V2/R, then derate generously (×2 or more) for safety and temperature rise. - Pick the mounting technology

- Dense, automated design → SMD (0402–1206).

- High power, high voltage, easy probing or rework → consider axial THT.

- Match package to power + PCB space

- For low-power logic lines, 0402–0603 at 1/20–1/10 W is often sufficient. EEPower

- For current-limiting, bleeder resistors or power paths, move up to 1206/1210/2512 or axial 1/2–1 W parts.

- Check lead / pad geometry vs assembly equipment

- For THT: body diameter and lead diameter should fit your automatic lead forming and cutting equipment as well as your PCB hole and pad design.

- For SMT: verify land patterns per datasheet and your assembly house’s design rules.

- Confirm availability & cost

Some “exotic” combinations (e.g., very high precision, very high power, very small size) can be expensive or long-lead.

8. How Package Size Interacts With Lead Forming and Automation

If your production line includes automatic resistor lead forming machines, package and lead geometry are not theoretical—they define whether your line runs smoothly:

- Body length and diameter affect how close to the body you can cut and bend without cracking the coating.

- Lead diameter and material determine the bending radius and the forming force your tooling must apply.

- Lead spacing after forming must match PCB hole spacing (5.08 mm, 7.62 mm, 10.16 mm, etc.), which are tied back to the standard sizes in Table 2.

Standardizing packages (for example, using mostly 1/4 W and 1/2 W axial resistors on THT lines) simplifies both tooling setup and inventory management and reduces scrap in high-volume production. AnyPCBA

9. Recommended Further Reading & Internal Resources (Internal Links)

To go deeper and connect package size to your broader component and process strategy, you can refer to:

- Resistor lead forming equipment and process compatibility

Learn how different resistor lengths, diameters and pitches affect forming quality and productivity on automatic lines:

👉 Resistor lead forming machine - Component parameter basics for buyers and engineers

A broader view on voltage rating, tolerance, TCR and other specs that matter alongside package size:

👉 Electronic component parameter guide - Choosing precision vs general-purpose resistors

When does it make sense to pay for tighter tolerance and which packages are typically available for those parts:

👉 Precision vs standard resistor selection guide

You can adapt the anchor text and exact URLs to match your existing site structure, but keeping 2–3 focused, context-relevant internal links like these helps both SEO and user navigation.

10. Key Takeaways

- Package size is not cosmetic—it encodes power rating, manufacturability and reliability.

- Common SMD sizes like 0402, 0603, 0805, 1206 are well standardized in both imperial and metric units; use the smallest size that still gives comfortable power margin.

- Axial resistor sizes scale with wattage; 1/4 W and 1/2 W remain the workhorses of many power and industrial boards.

- MELF packages serve niche applications that demand high stability and low TCR.

- For high-volume production, always choose package sizes that are friendly to your lead forming, cutting and insertion equipment, not just your schematic.

If you align electrical requirements, PCB constraints and assembly capability, picking the “right” resistor package size becomes a straightforward, repeatable decision instead of a guessing game.

What are the most common SMD resistor package sizes?

The most common SMD resistor package sizes are 0402, 0603, 0805 and 1206. They follow JEDEC standards for length and width and each size has a typical power rating, from around 1/16 W up to 1/4 W or more depending on the series and manufacturer.

How do I choose the right resistor package size for my design?

Start from the required power dissipation and apply a comfortable derating factor. Then consider PCB space, assembly method and automation. For dense digital circuits, 0402 or 0603 usually work well. For higher current or higher temperature, larger sizes like 0805, 1206 or 2512—or axial through-hole resistors—provide more power margin.

What is the difference between 0603 and 0805 resistor sizes?

Both are common SMD chip resistor packages, but 0805 is physically larger and can usually handle more power than 0603. 0603 saves PCB space but has smaller pads and slightly lower power rating, while 0805 offers easier assembly and more robust power handling in many power supply and industrial applications.

Are axial resistor sizes standardized by power rating?

Yes. Axial resistor body length and diameter roughly scale with power rating, such as 1/4 W, 1/2 W and 1 W. Exact dimensions vary by manufacturer, but most follow similar size families so that automated lead forming and PCB hole spacing remain compatible.

Related Posts

20 Years of Expertise, Trusted by Clients Worldwide

The Preferred Choice of Foxconn, BYD, and Huawei