- Blog

Solving the Heatsink Screw Locking Challenge: Key Features and Advantages of the High-Efficiency Heatsink Screw Locking Machine

- By tian81259@gmail.com

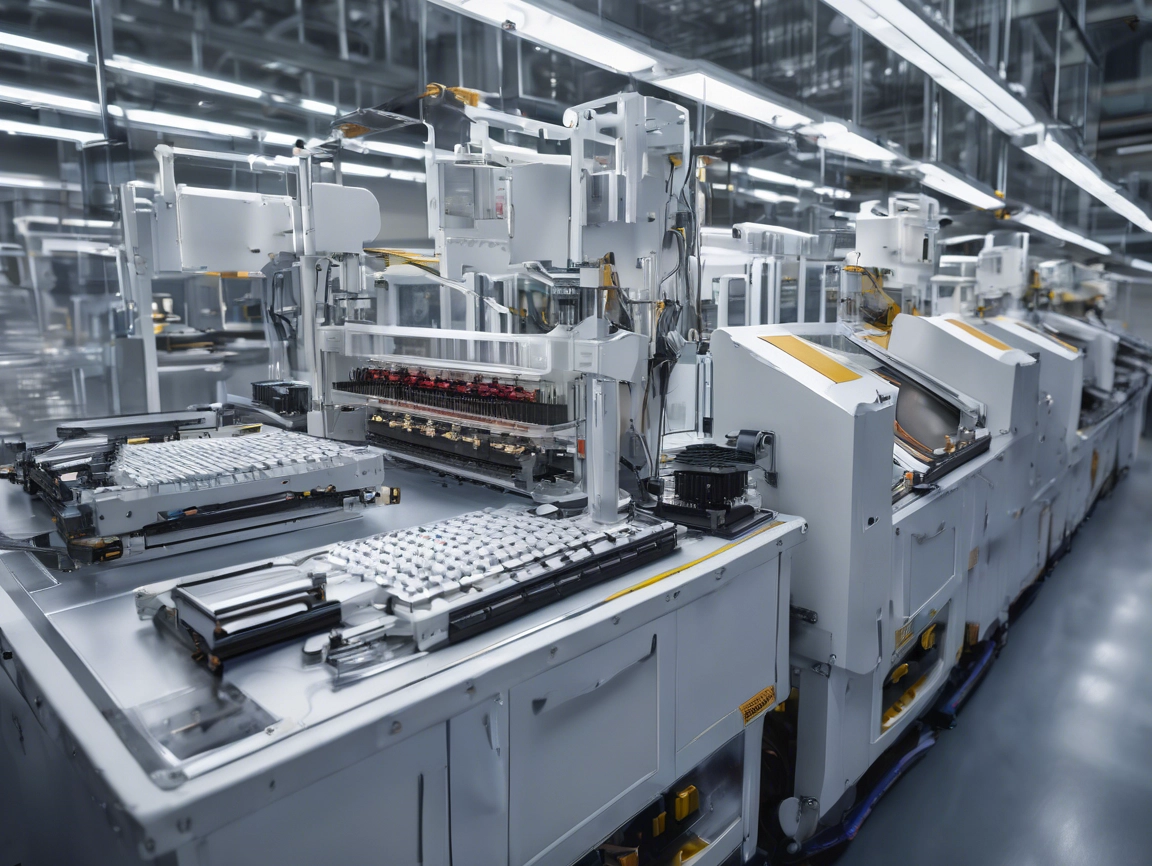

A heatsink screw locking machine is an automated device specifically designed for the assembly process of heatsinks, widely used in industries such as electronic components manufacturing, automotive electronics, power electronics, and home appliances. During the production of control boards for household appliances, automotive electronics, and power products, multiple transistors are often locked onto a standard or irregular-shaped heatsink, with the installation of insulating sheets, insertion of insulating particles, and multiple thermal paste scraping steps. When done manually, such a complex process can affect the consistency of components and result in low efficiency and limited production capacity. Through efficient automation, this machine can handle the complex task of locking multiple transistors onto heatsinks and fully automate the processes of placing insulating sheets, inserting insulating particles, scraping thermal paste, and more. The heatsink screw locking machine not only improves production efficiency but also ensures the stability of product quality. In this article, we will introduce the basic features and advantages of the heatsink screw locking machine, providing reference ideas for production line upgrades.

Basic Features of the Heatsink Screw Locking Machine

1.Fully Automated Operation

The heatsink screw locking machine adopts a fully automated control system with PLC control and touch screen operation. It automatically performs foot cutting of transistors, scraping of thermal paste, placement of insulating sheets and particles, transistor placement, and automatic screw feeding and locking, greatly reducing human intervention, minimizing operational errors, and improving production efficiency. The equipment automatically completes multiple processes, including screw feeding, locking, and inspection.

2.High Production C2.High Production Capacity

The machine is equipped with high-speed screw locking capabilities. A single machine can achieve an output of thousands of screws per hour, significantly enhancing the production line’s efficiency and reducing production costs.

3.Multi-Function Adaptability

The heatsink screw locking machine can be customized to meet the customer’s needs, adapting to different screw types and hole designs. It supports various screw head types (such as flathead, cross, hexagon, etc.). Additionally, the machine can implement segmented torque control for different torque stages, ensuring precise locking effects.

4.Intelligent Detection and Feedback

The machine is equipped with an intelligent detection system that can monitor the locking status of each screw in real-time, ensuring that no screws are missed or incorrectly locked. If any anomalies are detected, the system will alert the operator, ensuring smooth production.

5.Assembly Line Structure

The machine adopts an assembly line structure with multiple workstations, each of which can be individually adjusted, reducing the difficulty of debugging. Many workstations are designed as complex assembly stations, enabling the integration of various functions and accommodating complex assembly processes.

6.Non-Standard Customization

This is a non-standard customized machine, designed to meet the specific assembly process needs of the customer. It is capable of satisfying the requirements of various complex assembly processes and is already successfully applied in production lines for TV control boards, air conditioner heatsinks, power supply modules, and other products requiring heatsink locking.

7.Energy-Efficient and Environmentally Friendly

The heatsink screw locking machine is designed with energy consumption in mind, optimizing electrical systems and drive mechanisms to reduce energy use. The compact design and small footprint also help save production space

Advantages of the Heatsink Screw Locking Machine

1.Improved Production Efficiency

By replacing manual operations with automation, the heatsink screw locking machine significantly increases the efficiency of the production line. The equipment can operate 24/7, ensuring continuous and stable production, thus greatly boosting output.

2.Ensured Product Quality

The automated operation ensures that each screw is locked with high precision and consistency. The machine’s high-precision control system effectively prevents quality fluctuations caused by human errors, ensuring that each product meets the required locking strength and safety standards.

Positioning System Technology

Many machines are equipped with visual recognition systems (such as CCD cameras) and high-precision guide rails, ensuring that screw hole position errors are controlled within ±0.05mm. Some models use laser distance measurement aids, ensuring screw verticality deviation is less than 0.5°, reducing poor contact caused by tilting.

Torque Control Optimization

The machine uses a combination of torque sensors and programmable controllers to adjust torque between 0.01 – 5N·m. After manufacturers started using this type of machine in 5G base station heatsink modules, the deformation rate of heatsinks due to over-tightening screws dropped from 12% to below 1.5%, significantly improving product reliability.

| Lock payment method | Error margin | Verticality deviation |

| Manual operation | ±0.3mm | 1 – 3° |

| Equipment Operation | ±0.05mm | <0.5° |

3.Reduced Labor Costs

Through automation, the heatsink screw locking machine reduces the reliance on manual labor, lowering personnel costs and labor intensity. Operators only need to add minimal materials, significantly reducing manpower input and minimizing production delays and errors caused by human factors.

4.Improved Production Safety

The heatsink screw locking machine features advanced safety protection designs with multiple safety mechanisms to ensure operator safety during use. The automated operation also eliminates the safety risks associated with manual operations.

5.Flexibility and Adaptability

The machine can be quickly adjusted to accommodate different products and screw locking requirements. Whether for mass production or custom orders, the machine provides efficient and flexible solutions.

6.Enhanced Competitiveness

By adopting the heatsink screw locking machine, companies can not only drastically improve production efficiency and product quality but also lower costs, thereby enhancing their competitiveness in the market. With continuous optimization of the equipment, businesses can maintain a strong position in the competitive market.

In today’s pursuit of efficient, high-quality, and low-cost manufacturing, the heatsink screw locking machine is no longer an “optional” tool but a “must-have” weapon for enhancing a company’s core competitiveness. Its exceptional precision, remarkable efficiency, stable reliability, and significant cost advantages make it the best solution to address the challenges of the heatsink locking process.

Shenzhen Flourishe Electronic Technology Co., Ltd. specializes in providing high-performance and stable heatsink screw locking solutions. With extensive industry experience, we can customize the most optimized equipment configuration based on your specific heatsink product and production needs.

Related Posts

20 Years of Expertise, Trusted by Clients Worldwide

The Preferred Choice of Foxconn, BYD, and Huawei