- Industry News

What Are the Main Types of Electronic Components? A Practical Guide to Resistors, Capacitors, Inductors, Diodes, Transistors & IC

- By tian81259@gmail.com

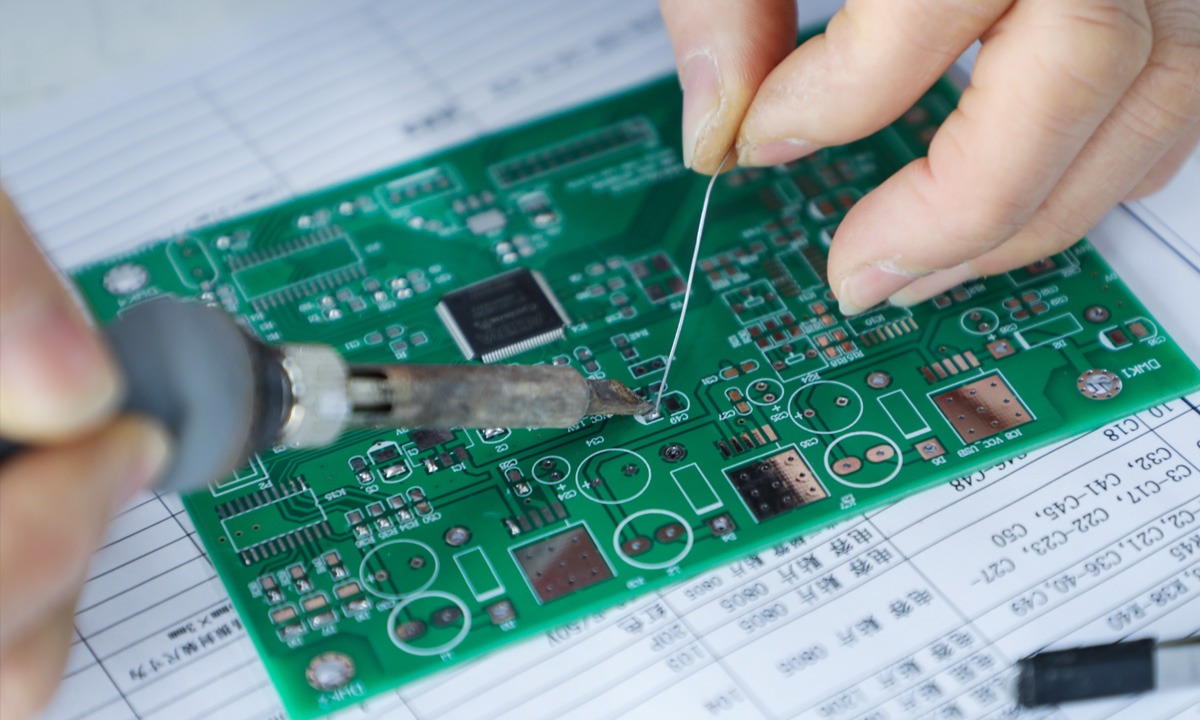

Strip any circuit board down to the essentials and you’ll keep seeing the same building blocks over and over again: resistors, capacitors, inductors, diodes, transistors, and integrated circuits (ICs). Whether you’re a purchasing manager, hardware startup founder, or junior engineer, understanding these core component families is the foundation for better design decisions, supplier communication, and cost control.

This guide explains what each type of component does, how it’s used in real products like power supplies and control boards, and what you should pay attention to when you’re selecting or buying them. We’ll also briefly touch on how these components are assembled in volume production and where electronic component forming machines fit into a modern electronics line.

1. Passive vs. Active Components: The Big Picture

Most electronic components fall into two broad categories:

- Passive components – Resistors, capacitors, and inductors. They don’t provide gain; they store, shape, or dissipate energy.

- Active components – Diodes (in many contexts), transistors, and ICs. They can control current flow, and transistors/ICs can amplify signals and perform logic.

Authoritative resources such as All About Circuits and Electronics-Tutorials use the same classification: passive parts shape voltage and current, while semiconductors like transistors and ICs actively control signals and power.

2. Resistors: Controlling Current and Setting Voltage

A resistor is a passive two-terminal component whose job is to limit current and set voltage levels. It obeys Ohm’s law (V = I × R), and you see it everywhere from LED current limiting to precision sensing in power supplies.

2.1 What resistors actually do

- Limit current into LEDs, IC pins, and sensors.

- Form voltage dividers to create reference voltages.

- Bias transistors and op-amps to operate in the correct region.

- Sensing – low-value “shunt” resistors measure current in power systems.

2.2 Key parameters when selecting resistors

- Resistance value (Ω) – for example 10 Ω, 1 kΩ, 1 MΩ.

- Tolerance – ±1%, ±5%, etc. determines precision.

- Power rating (W) – how much heat it can safely dissipate.

- Temperature coefficient – stability over temperature (ppm/°C).

- Package type – through-hole (axial) vs SMD (0402, 0603, 0805, 1206… ).

For a deeper technical overview, many engineers rely on open references like the resistor sections of All About Circuits’ DC textbook, which walks through resistor types, color codes, and real-world considerations.

2.3 Manufacturing note: resistor lead forming

In high-volume power supplies, adapters, and control boards, axial resistors are often still used for high power or high reliability. Before insertion, their leads must be cut, bent, and pre-formed to the correct pitch. Doing this by hand is slow and inconsistent; many factories now rely on resistor lead forming machines and other electronic component forming machines to standardize lead length, bending angles, and insertion efficiency.

3. Capacitors: Storing Energy in an Electric Field

A capacitor stores electrical energy in an electric field between two plates separated by a dielectric. According to manufacturer design guides from companies like Murata and KEMET, capacitors are essential for decoupling, filtering, timing, and energy storage in almost every modern circuit.

3.1 What capacitors do in real circuits

- Decoupling / bypass – stabilize IC supply rails and absorb noise.

- Filtering – smooth AC ripple in power supplies and shape audio/RF signals.

- Timing – RC networks set delays and oscillator frequencies.

- Energy storage – bulk capacitors provide hold-up in power supplies.

3.2 Common capacitor types

- Ceramic capacitors (MLCCs) – small, low ESR, ideal for decoupling and RF work.

- Aluminum electrolytic capacitors – large capacitance; used for smoothing and energy storage in power converters.

- Tantalum capacitors – high capacitance in small packages; used in high-density electronics with controlled conditions.

- Film capacitors – stable and low loss; used in EMI filters, audio, and high-frequency AC applications.

When evaluating capacitor lifetime, power-electronics designers often reference application notes from vendors such as Nichicon and Panasonic, which explain how temperature, ripple current, and voltage stress combine to determine long-term reliability.

4. Inductors: Energy in a Magnetic Field

An inductor is typically a coil of wire that stores energy in its magnetic field. It resists changes in current, which is exactly why it’s critical in power converters and EMI filters.

4.1 Typical inductor applications

- Switch-mode power supplies – inductors and transformers set energy transfer per cycle.

- EMI filters – common-mode chokes reduce conducted noise.

- RF circuits – used in filters, oscillators, and matching networks.

4.2 Key parameters

- Inductance (H) – how much energy is stored for a given current.

- Saturation current – beyond this, the core’s inductance collapses.

- DC resistance (DCR) – affects conduction losses and efficiency.

- Self-resonant frequency (SRF) – above SRF, the inductor’s behavior becomes capacitive.

Many designers refer to component vendor data and handbooks like Vishay, Coilcraft, or Würth Elektronik application notes when selecting inductors for specific topologies and frequencies.

5. Diodes: One-Way “Valves” for Current

A diode is a semiconductor device that ideally allows current to flow in one direction and blocks it in the other. Semiconductor fundamentals texts and resources like Electronics-Tutorials’ diode series define it as the simplest PN-junction device, but its role in protection and rectification is critical.

5.1 Common diode types

- Rectifier diodes – convert AC to DC in power supplies.

- Schottky diodes – low forward voltage and fast switching; widely used in high-frequency converters.

- Zener diodes – provide voltage regulation and over-voltage protection.

- TVS (Transient Voltage Suppressor) diodes – protect against ESD and surge events.

- LEDs (Light Emitting Diodes) – emit light when forward-biased; used in indicators and lighting.

In many BOMs, axial diodes (e.g., rectifiers or signal diodes) are still supplied as through-hole parts. Just like resistors, their leads are often pre-cut and formed using electronic component forming machines for consistent insertion depth and solder quality.

6. Transistors: Switches and Amplifiers of Modern Electronics

A transistor is a semiconductor device used to amplify or switch electrical signals and power. It is one of the fundamental building blocks of modern electronics. According to device manufacturers such as Texas Instruments, ON Semiconductor, and Infineon, the world of transistors can be broadly split into BJTs and FETs.

6.1 Main transistor families

- Bipolar Junction Transistor (BJT) – uses a small base current to control a larger collector current. Common in analog amplification and some switching applications.

- MOSFET (Metal-Oxide-Semiconductor FET) – uses a gate voltage to control the current between source and drain. Dominant in power electronics and digital logic.

- IGBT (Insulated Gate Bipolar Transistor) – combines MOSFET gate drive with BJT-like conduction; widely used in motor drives, inverters, and industrial power.

6.2 Typical transistor applications

- Power conversion – switching MOSFETs and IGBTs in chargers, adapters, inverters, and motor drives.

- Signal amplification – small-signal BJTs and FETs in audio, instrumentation, and RF front ends.

- Digital logic – billions of MOSFETs are integrated into CPUs, MCUs, and ASICs.

For design-level detail, engineers frequently consult semiconductor manufacturers’ application notes, which cover safe operating area (SOA), gate-drive considerations, and thermal management for power transistors.

7. Integrated Circuits (ICs): Systems on a Chip

An integrated circuit (IC) is a tiny semiconductor die (usually silicon) that combines many transistors plus supporting resistors, capacitors, and diodes into one package. Widely used references like Wikipedia and semiconductor textbooks describe ICs as the reason modern electronics can integrate complex functions into small, low-cost devices.

7.1 Major IC categories

- Digital ICs – microcontrollers (MCUs), microprocessors (CPUs), FPGAs, memory.

- Analog ICs – op-amps, comparators, linear regulators, precision references.

- Mixed-signal ICs – ADCs, DACs, motor drivers, RF transceivers, power-management ICs.

7.2 Common IC packages

- Through-hole – DIP, SIP (still seen in some industrial and legacy designs).

- SMD – SOIC, TSSOP, QFP, QFN, BGA, and many variants.

In modern manufacturing, ICs are almost always surface-mount and placed by pick-and-place machines. However, through-hole ICs still appear in repair-friendly or high-reliability designs, and those packages must be considered when planning your assembly process and wave soldering profile.

8. Through-Hole vs. Surface Mount: Why Assembly Method Matters

From a design and purchasing standpoint, it’s not enough to know what a component does electrically. You must also understand how it will be mounted on the PCB and what that means for cost and reliability.

8.1 Through-hole technology (THT)

- Components have leads that pass through holes in the PCB and are soldered on the opposite side.

- Common for high-power parts, large capacitors, connectors, and some industrial components.

- Provides strong mechanical strength, which is why it remains popular in automotive and industrial control boards.

In THT lines, components like resistors, diodes, and capacitors often arrive as tape-and-reel or ammo packs and must be cut, bent, and formed to the correct geometry. Instead of doing this manually, many factories use dedicated electronic component forming machines to standardize lead length and bending angles, reduce operator fatigue, and improve overall solder consistency. For a deeper dive, see our internal guide: Lead Formers Buying Guide for Power Electronics & Control Boards.

8.2 Surface-mount technology (SMT)

- Components are soldered directly onto pads on the PCB surface, no drilled hole needed for each lead.

- Enables high-density designs with shorter signal paths and lower parasitics.

- Assembly is highly automated: solder paste printing, pick-and-place, and reflow soldering.

Most new designs are predominantly SMT, with THT reserved for mechanically or thermally stressed components. For procurement, this means you often need both SMD and through-hole versions of similar component types, depending on the product line and assembly process.

9. How to Choose the Right Components: A Practical Checklist

When you’re specifying or purchasing resistors, capacitors, inductors, diodes, transistors, and ICs, a structured approach helps avoid painful redesigns and field failures.

- Clarify the function

- Is the part limiting current, filtering noise, storing energy, switching power, or processing signals?

- Define electrical stress

- Voltage, current, power dissipation, frequency, surge events.

- Consider environment & reliability

- Operating temperature range, humidity, vibration, expected lifetime.

- Do you need automotive grade (AEC-Q), industrial grade, or consumer grade components?

- Match package to assembly process

- SMT vs THT (or a mix).

- For THT, plan for lead forming, insertion, and wave soldering. Automation with forming machines can significantly reduce labor cost.

- Check standards & certifications

- Depending on market, you may need UL, IEC, or automotive standards compliance.

- Datasheets and safety approvals from reputable manufacturers (TI, ST, Infineon, Vishay, etc.) are strong signals of quality.

- Validate supply chain

- Look for multiple qualified sources and avoid parts near end-of-life (EOL).

- For critical components, consider second-source compatibility early in the design.

10. FAQ: Quick Answers About the Main Component Types

Q1. Which components should a beginner understand first?

Start with resistors, capacitors, and diodes. Once those make sense, move to inductors and transistors. ICs are built on top of these primitives; the more you understand the basics, the easier it is to understand what an IC is doing internally.

Q2. Why do some designs still use through-hole parts in the SMT era?

Through-hole components offer better mechanical strength and are easier to rework. They are still widely used in power supplies, industrial controllers, and automotive electronics, especially for high-current connectors, big capacitors, and power resistors.

Q3. When does it make sense to use electronic component forming machines?

If your product uses large volumes of axial or radial through-hole components (for example, resistors, diodes, or capacitors) and you’re still doing manual cutting and bending, you’re likely leaving productivity and consistency on the table. Automating with electronic component forming machines can improve throughput, reduce rework, and make it easier to scale your line.

Conclusion

Resistors, capacitors, inductors, diodes, transistors, and ICs are more than just symbols on a schematic – they’re the core vocabulary of modern electronics. Understanding what each family does, how it behaves under stress, and how it is physically mounted on the PCB helps you:

- Communicate more effectively with engineers and suppliers.

- Make smarter BOM and sourcing decisions.

- Plan your assembly process, including when to automate with forming and insertion equipment.

As you build or optimize your own products – from chargers and adapters to industrial power supplies and control boards – a solid grasp of these component families is one of the simplest ways to improve reliability, cut costs, and streamline manufacturing.

Related Posts

20 Years of Expertise, Trusted by Clients Worldwide

The Preferred Choice of Foxconn, BYD, and Huawei